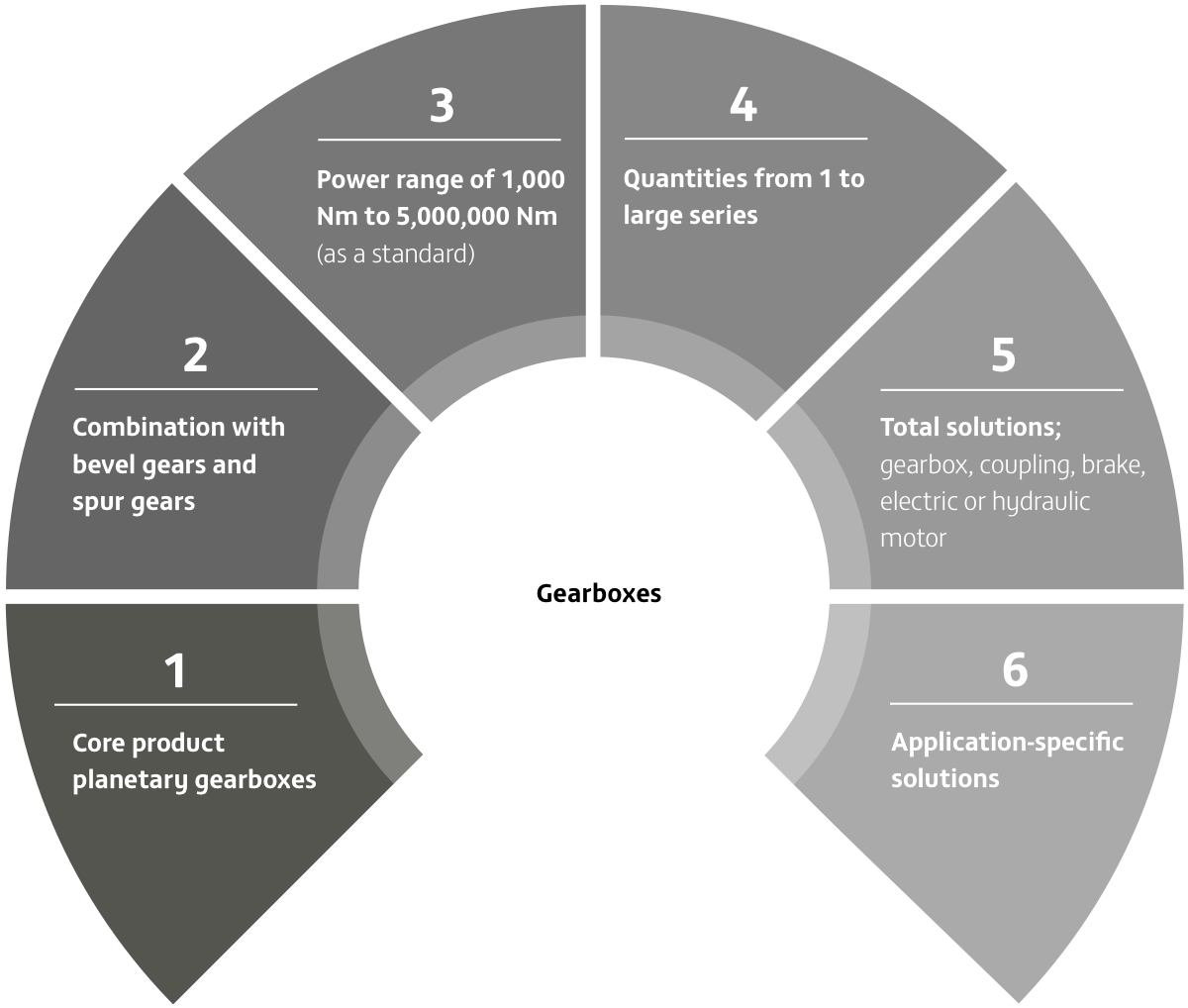

Versatile gearbox solutions

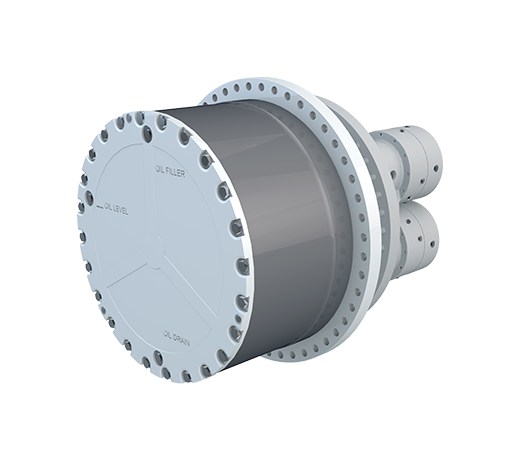

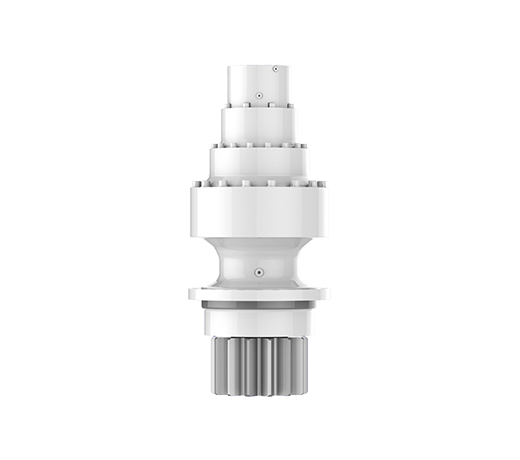

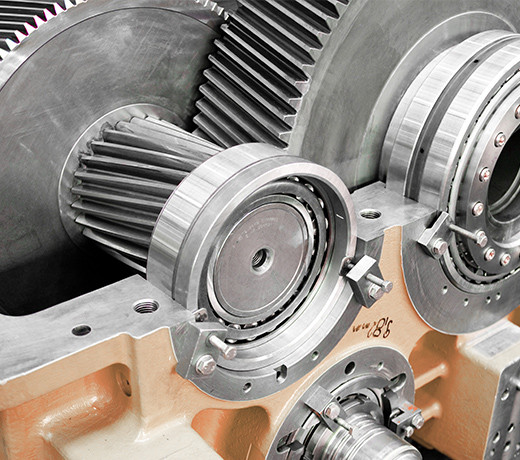

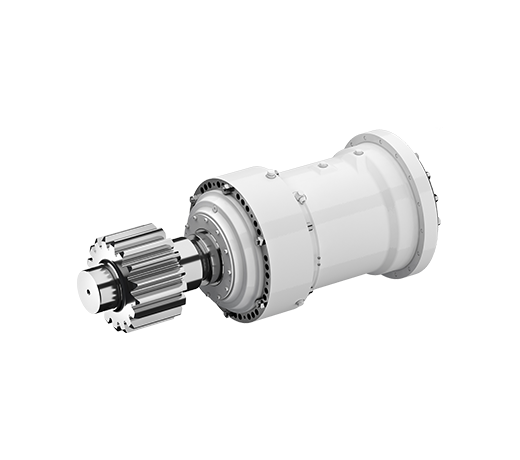

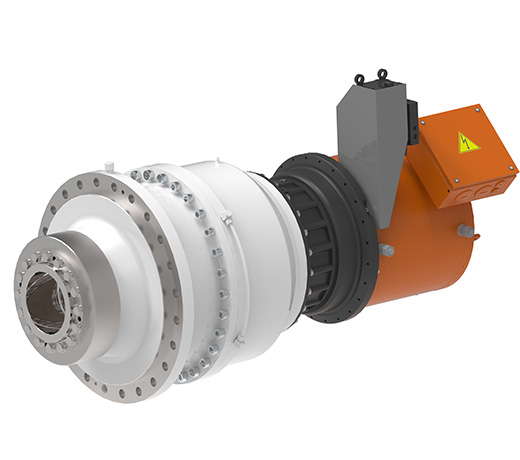

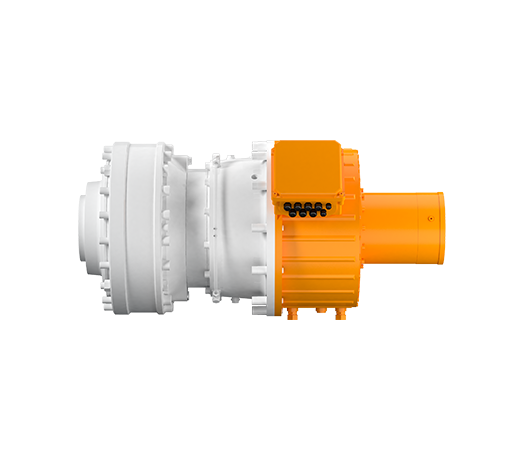

The core product of the ZOLLERN gearbox series is the planetary gearbox with its high efficiency and power density. It is based on a modular system which allows economic application-specific solutions.

ZOLLERN gearboxes are supplemented with additional elements of the drive train, such as the coupling, brake and motor and can be delivered as a complete system.

ZOLLERN has been producing planetary gearboxes since 1972. In 2001, the brand “Dorstener” and its gearbox technology for spur gears, bevel gears and planetary gears was acquired by the ZOLLERN Group.

Marine

ZOLLERN gearboxes and cable winches can be found in all maritime applications around the world. The ZOLLERN brand stands for excellent quality, reliability and innovation on ships, in harbours and on offshore platforms.

Typical application areas are ship cranes, heavy duty cranes, floating cranes, dredgers, lifeboat winches or jack-up gearboxes for offshore platforms. On land, for example, ZOLLERN moves mobile harbour cranes, shipyard cranes and handling equipment.

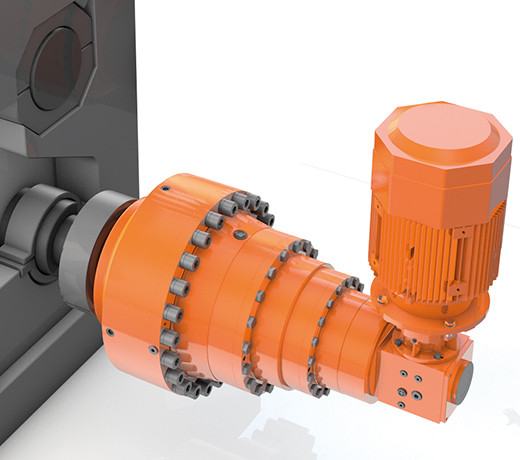

Construction machinery

ZOLLERN gearboxes and cable winches can be found in almost all construction equipment applications. The ZOLLERN brand is present worldwide and stands for excellent quality, reliability and innovation.

Typical application areas include mobile cranes, lattice boom cranes or tower cranes, drilling rigs and cable excavators. In addition, ZOLLERN is the benchmark for highly stressed drive components, such as in road milling, bucket wheel excavators or tunnel boring machines.

Industry

ZOLLERN gearboxes and cable winches can be found in various industrial applications. The ZOLLERN brand is present worldwide and stands for excellent quality, reliability and innovation.

Typical application areas in the field of raw materials production are oil platforms, mining excavators, dump and reloading equipment, bucket wheel excavators or tensioning systems for conveyor systems. In addition, sugar mills, shredder and mixing systems, roller pressers, extruders or calenders are driven by ZOLLERN drive technology.

Energy

ZOLLERN gearboxes and cable winches can be found in various industrial applications in energy and raw materials production. The ZOLLERN brand is present worldwide and stands for excellent quality, reliability and innovation.

Typical applications are oil platforms, mining excavators, dump and reloading equipment, bucket wheel excavators, tensioning systems for conveyor systems or pitch and azimuth gears for wind turbines.

ZOLLERN offers comprehensive service from the first product idea to the after sales service.

- Development partnership

- Technical and application-specific consultation

- Individual order processing, including scheduling agreements

- Comprehensive test run and test equipment (including load test)

- Intensive cooperation with classification societies

- Commissioning on site

Maintenance and repairs are performed in the adjacent service centre. The global service deployments and spare parts deliveries are coordinated from here.

- Quick spare parts deliveries with original spare parts

- Technical findings with repair report

- Error analyses, repairs and assembly work worldwide

- Retrofitting, revision and repair

- Reverse Engineering

- Maintenance service

- ZOLLERN training centre

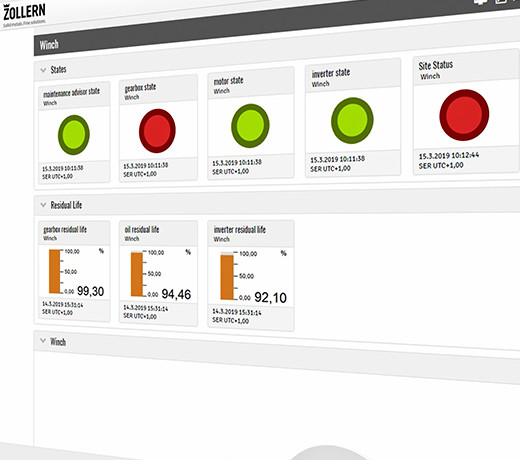

- Diagnostics and condition monitoring

- Service hotline

Give your ZOLLERN-Gearboxes and Winches a second life: with the ReDrive Program we ensure our gearboxes and winches can start a new lifecycle in top form, even after heavy use and prolonged operation.

With ZOLLERN ReDrive, we repair, overhaul, and modernize existing components – quickly and with high quality.

In order to avoid expensive downtimes when using gearboxes, ZOLLERN offers maintenance concepts that have been specially developed for gearboxes used in tunnel boring machines. The maintenance concepts can be transferred to all ZOLLERN gearboxes and winches and the different areas of application.