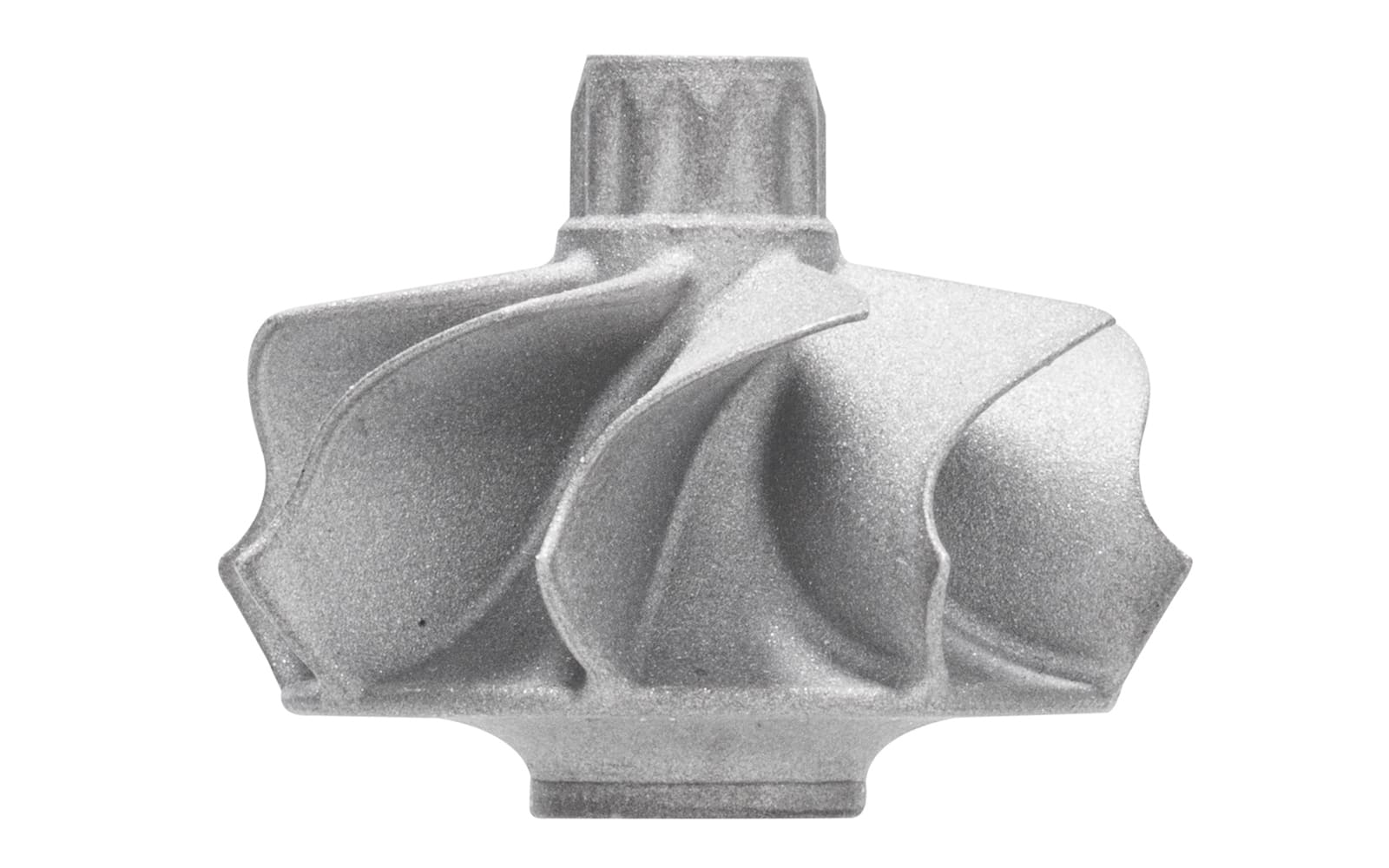

Vacuum investment casting

Ground tapping method

Highly productive melting and casting process for complex components made of highly heat-resistant materials. Large quantities can also be produced in a short period of time with a very high level of reproducibility.

- From individual parts to large series

- High degree of purity

- Possibility of targeted grain refinement on the castings

- High degree of automation

Tilting crucible method

Melting and casting process for the production of complex components made of high-temperature resistant materials with a high purity and very good reproducibility.

- From individual parts to large series

- Very high degree of purity

- High degree of automation in production, autonomous casting by casting cell (pre-heating to cooling)

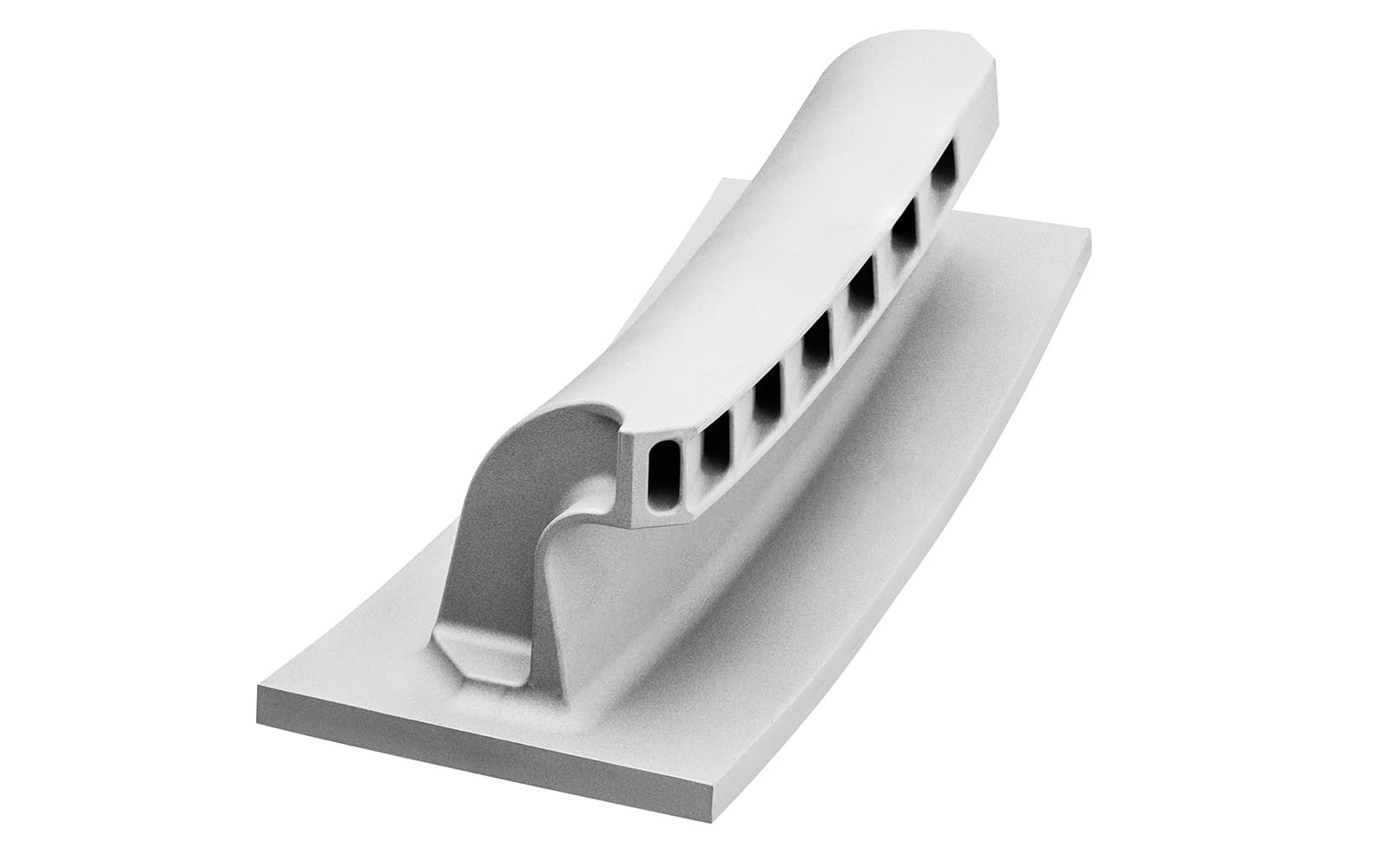

Open air investment casting

Conventional method

The conventional open investment casting - is a lost wax process that is characterised by an almost unlimited selection of alloys.

- Component weight up to 100 kg

- Manual pouring off of the casting cluster in an oxygenated environment

- The mould is filled manually via a ladle and is controlled by the casting speed

- Maximum installation space 600 x 600 x 550 mm

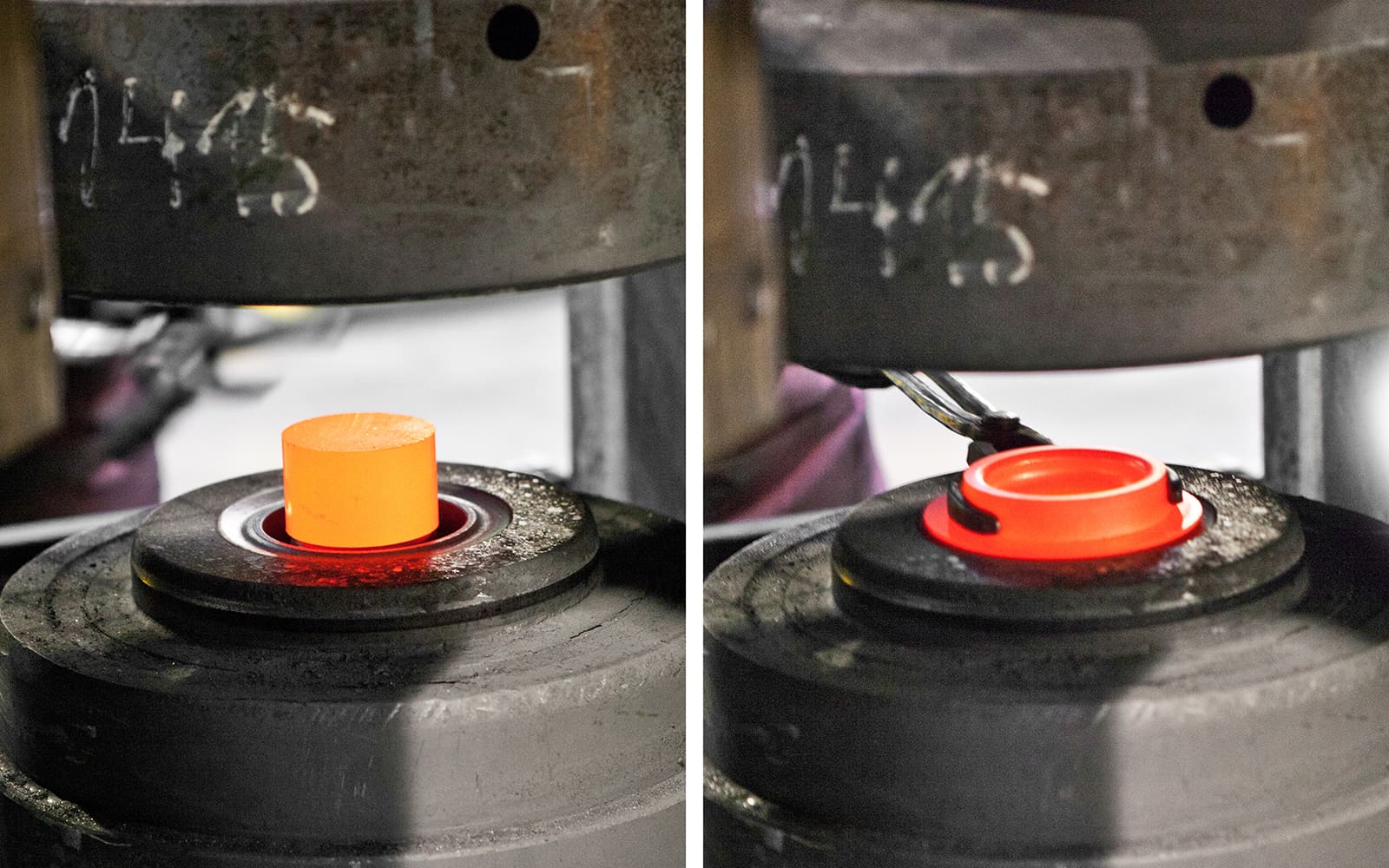

Roll-over technology

A very high material quality is achieved with roll-over technology. After melting the alloy, the furnace rotates 180 degrees in a few seconds. The mould shell that is flanged directly to the furnace is filled precisely and with low turbulence in the process, also while using inert gas.

- The influence of oxygen is eliminated by using an inert gas bell.

- The maximum installation space is 580 x 400 mm diameter

- Maximum casting weight of 100 kg

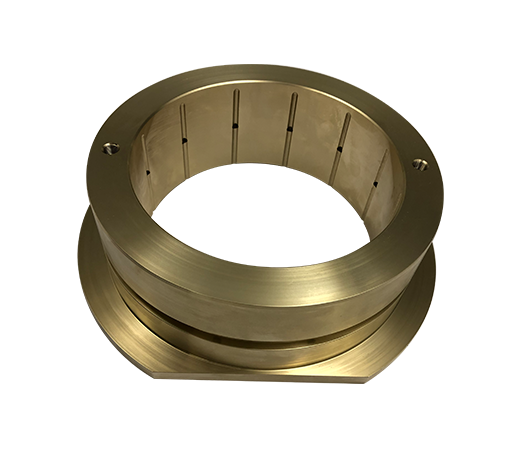

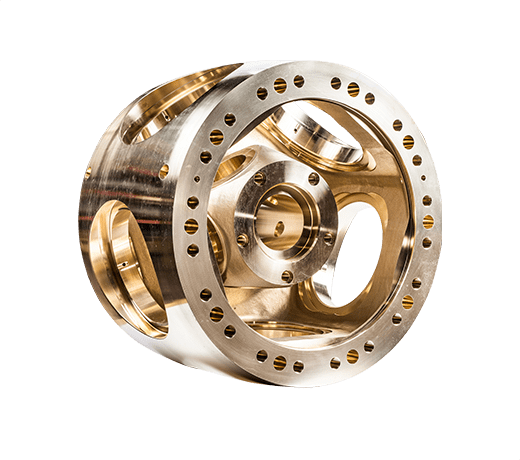

Sand casting

The sand casting process offers a high degree of freedom and the economic production of complex components with undercuts and cavities

- For individual parts and small series

- Production according to the permanent model, lost model or based on printed/milled moulded parts

- Part weights: Copper alloys up to 8,000 kg, steel alloys up to 2,500 kg

- Production using a lost mould

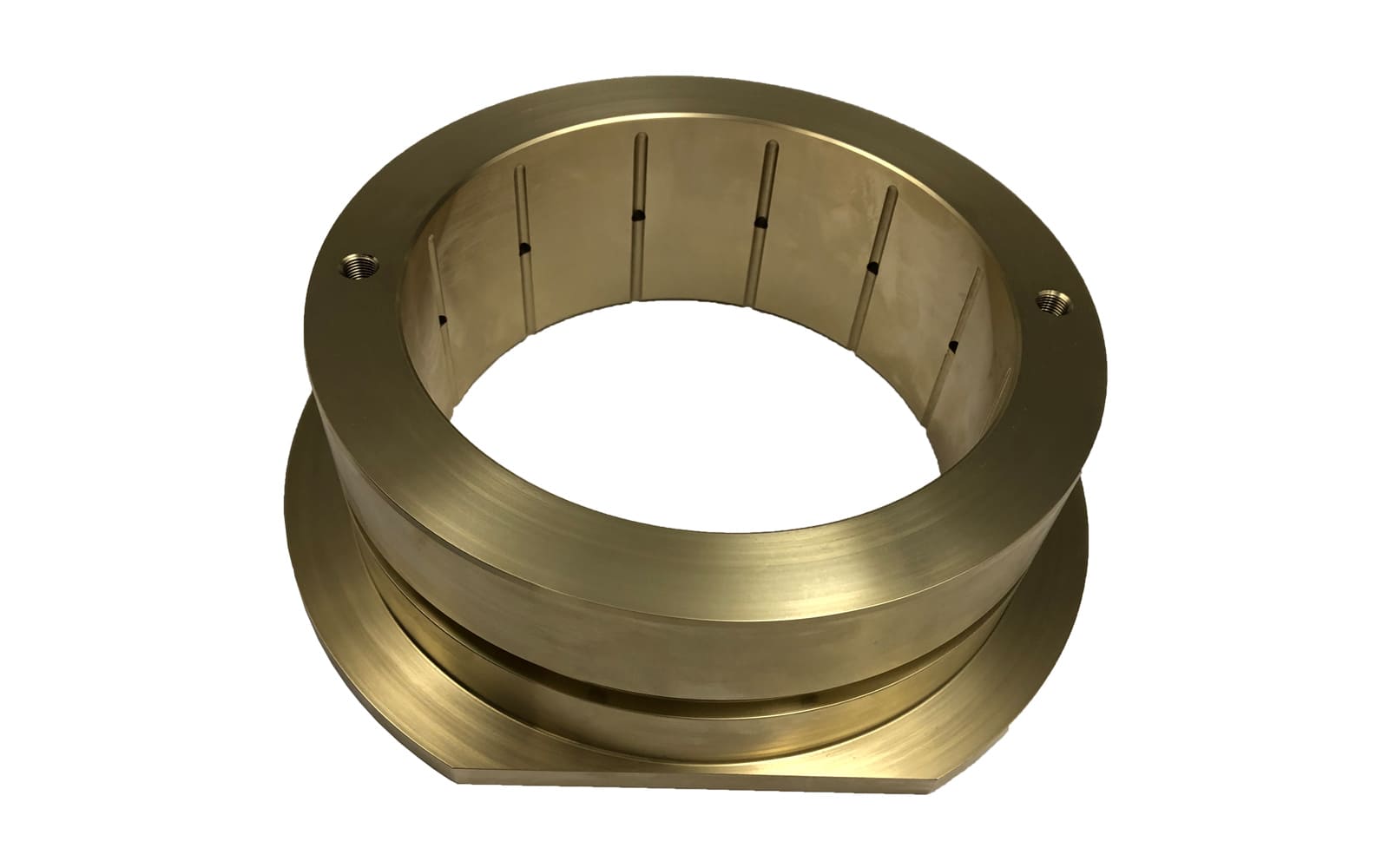

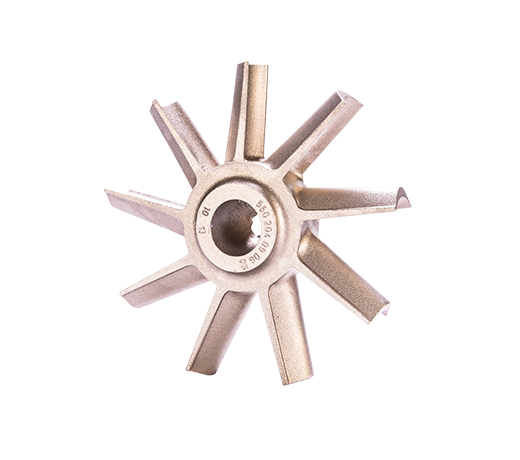

Croning casting / shell casting

Complex components with cavities and a high surface quality can be economically produced with Croning casting or shell casting.

- Surface quality Ra 6.3 µm

- Large series

- Metallic models

- Weight range up to about 20 kg

- Part dimensions up to about 400 x 250 x 200 mm

- Production using a lost mould

Direct Contact

P +49 (0) 7571 70 370

E zgm@zollern-nospam.com

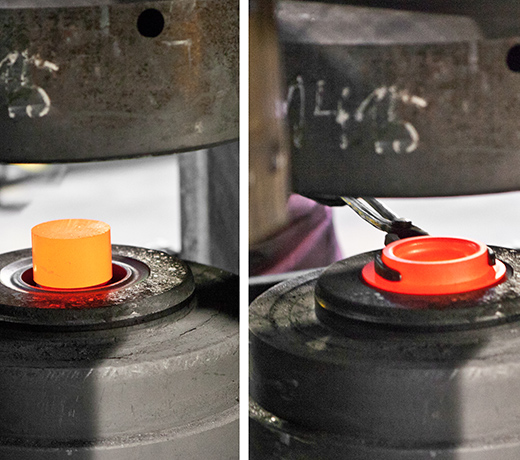

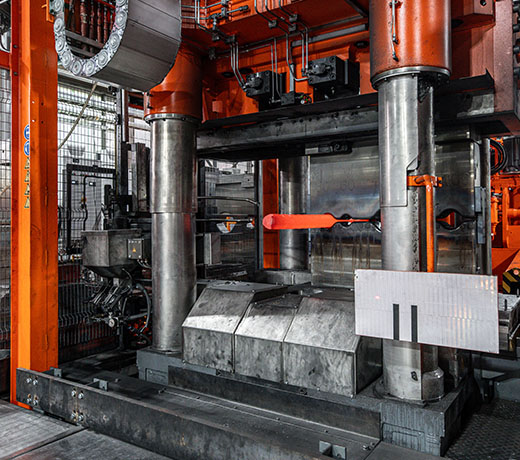

Process chain

ZOLLERN offers a high vertical range of manufacture for efficient processes and first-class quality.

- Master forming

- Metal forming

- Separating

- Changing material properties

- Machining

- Heat treatment

- NDT tests according to customer requirements (PT/UT/MT)

- Material testing (tensile test, notched bar impact test, hardness test, electrical conductivity)

- Metallographic examination (grain size determination, microstructure assessment, etc.)

Direct Contact

P +49 (0) 7571 70 370

E zgm@zollern-nospam.com

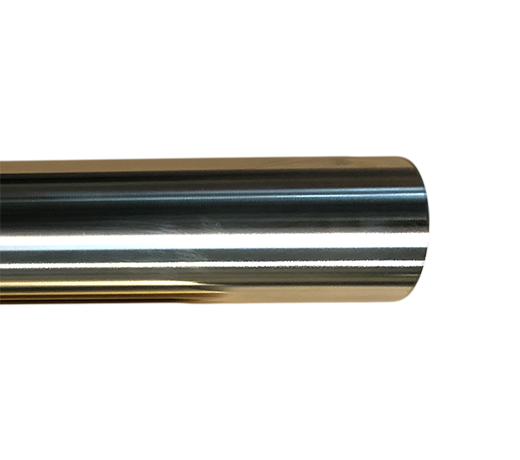

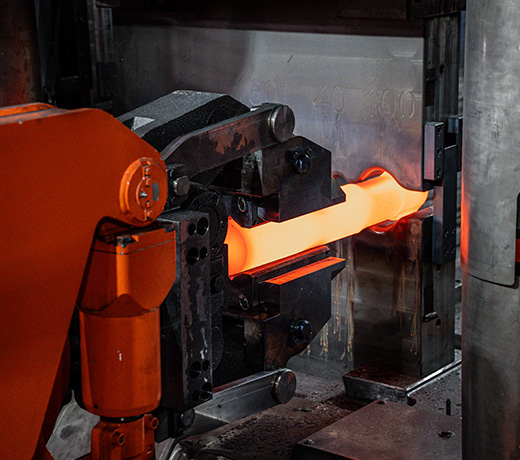

Cold rolling

With cold rolling, a wire rod is brought into the specified final contour at room temperature by rolling. Several rolling units in a production line automatically perform this process and give the profiles a high surface quality. The process is particularly well-suited for manufacturing small profile geometries, which are needed in larger quantities.

Direct Contact

P +49 (0) 7571 70-380

E zst@zollern-nospam.com