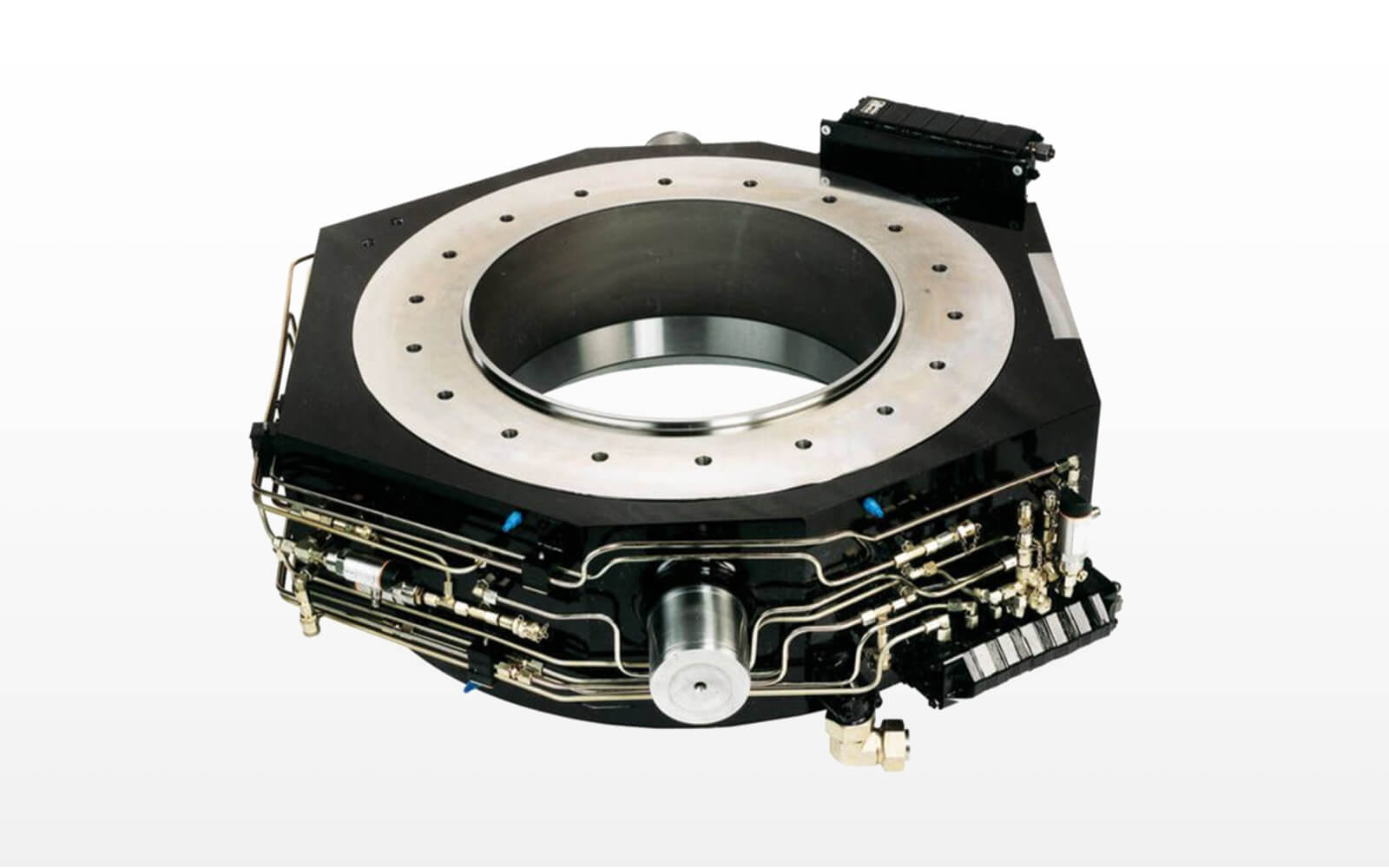

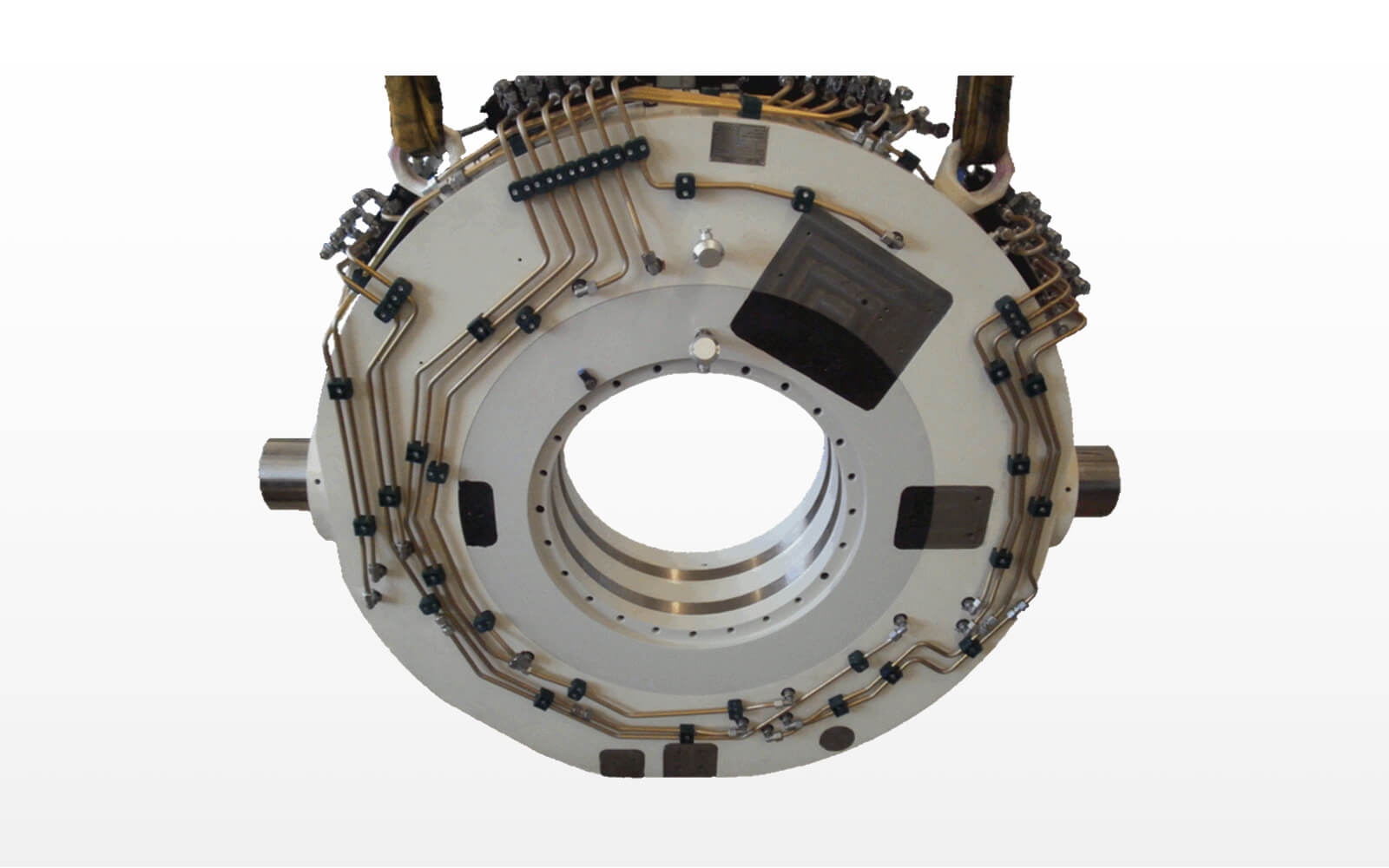

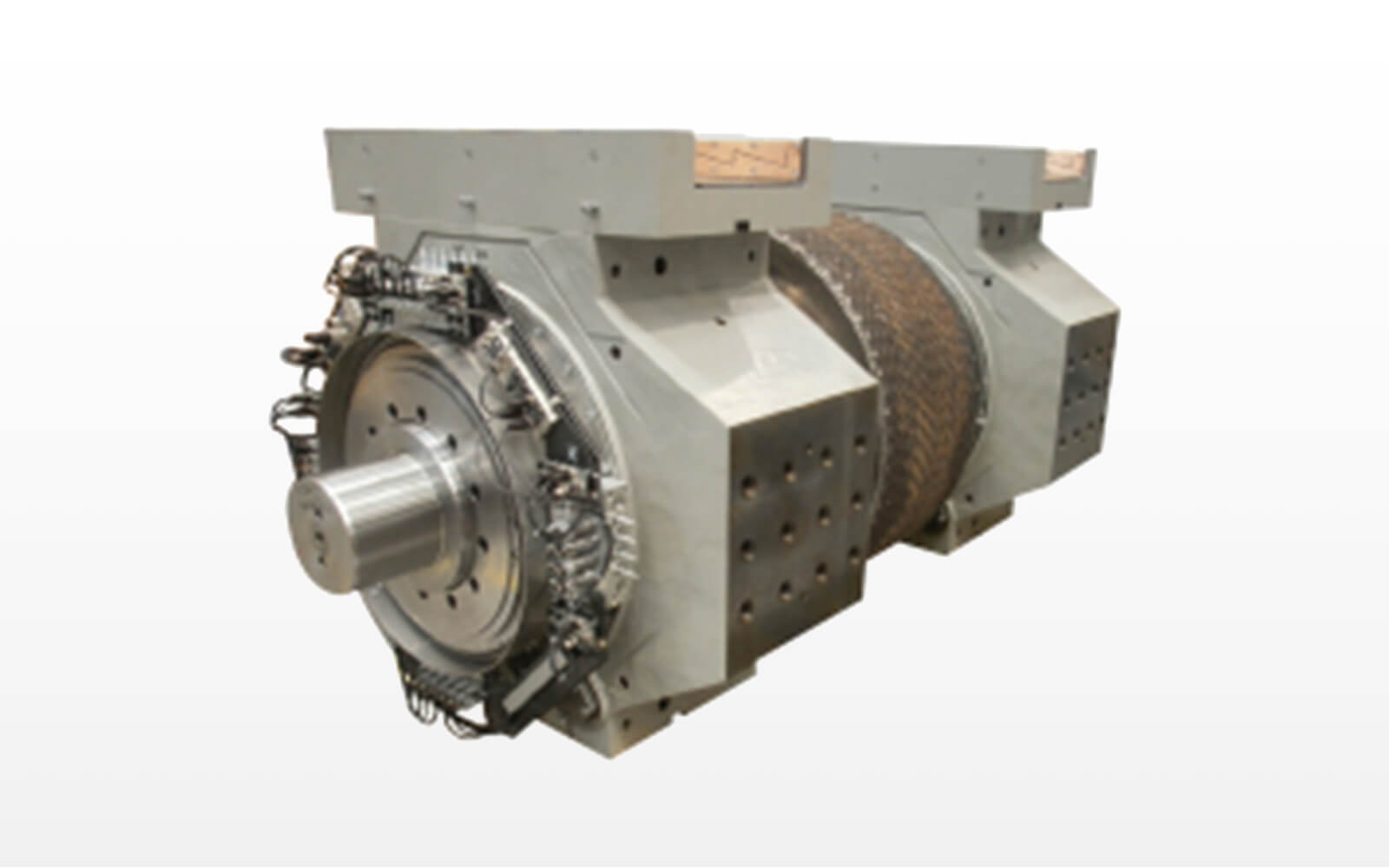

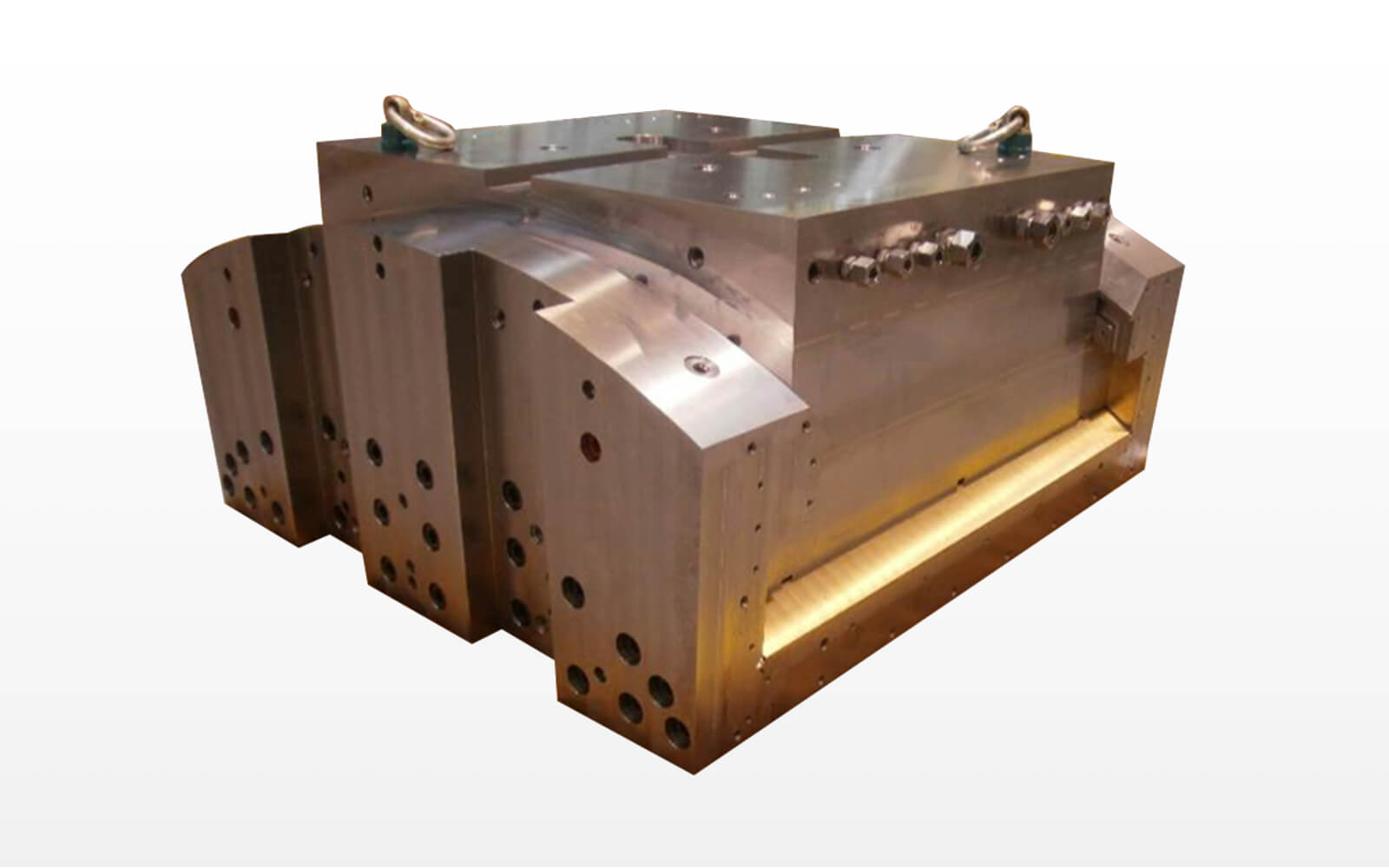

Testing and special applications

All the advantages of the concept of the hydrostatic bearing come to bear for testing and special applications. Depending on the application, it is the low friction, good damping, high level of running smoothness or the high bearing resilience that offer decisive advantages.

Product examples

Features, advantages

Features

- Friction-free at low speeds

- High damping due to the oil gap

- No vibrations from rolling elements

- High bearing resilience

- Combined radial and axial movement possible

Advantages

- Calculative unlimited service life

- Very high positioning accuracy

- Thermally stable, heat removal directly via the lubricating oil

Applications

- Test benches

- Cement mills

- Presses

- Telescopic bearings