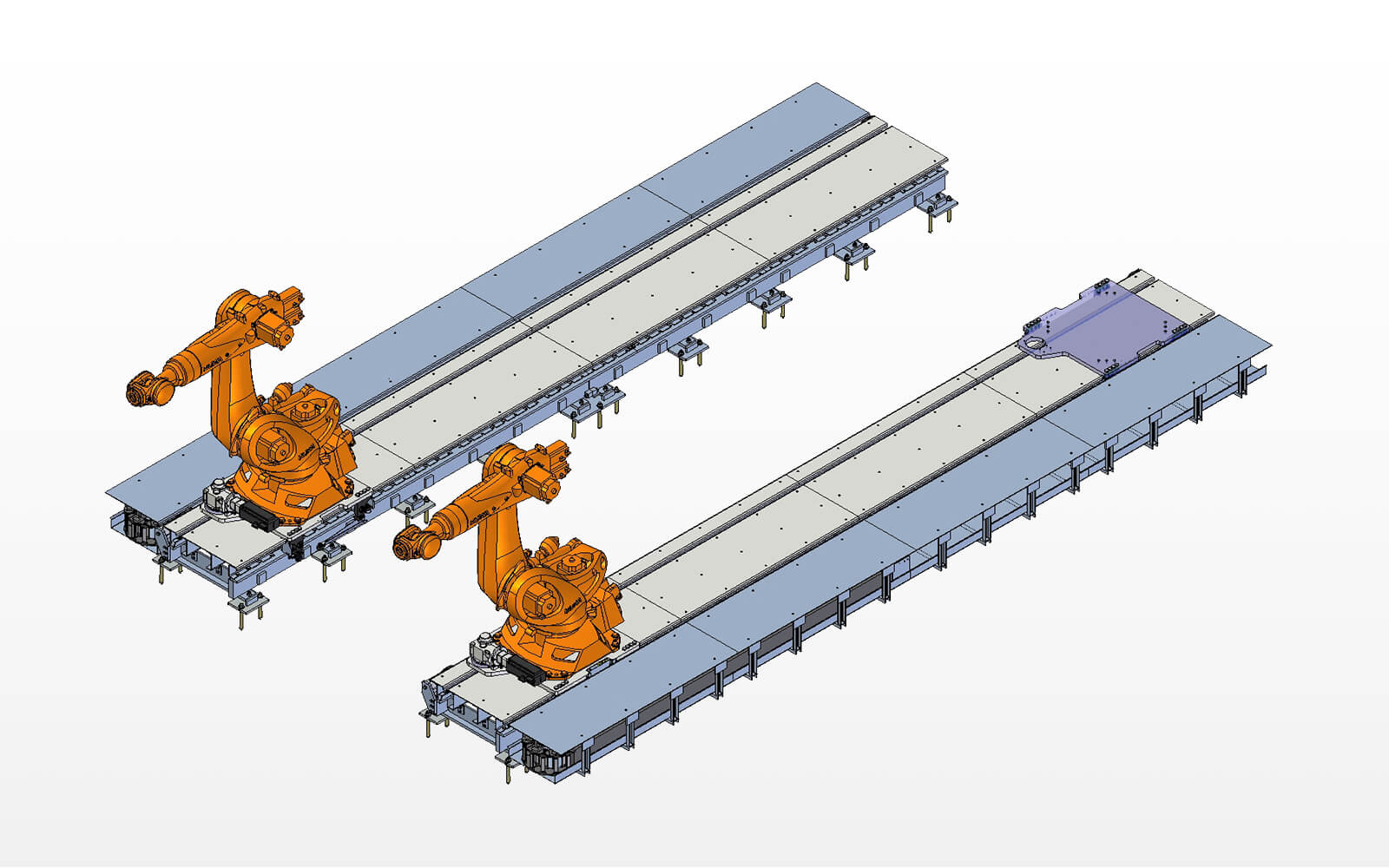

Robot traverse axes, jig axes

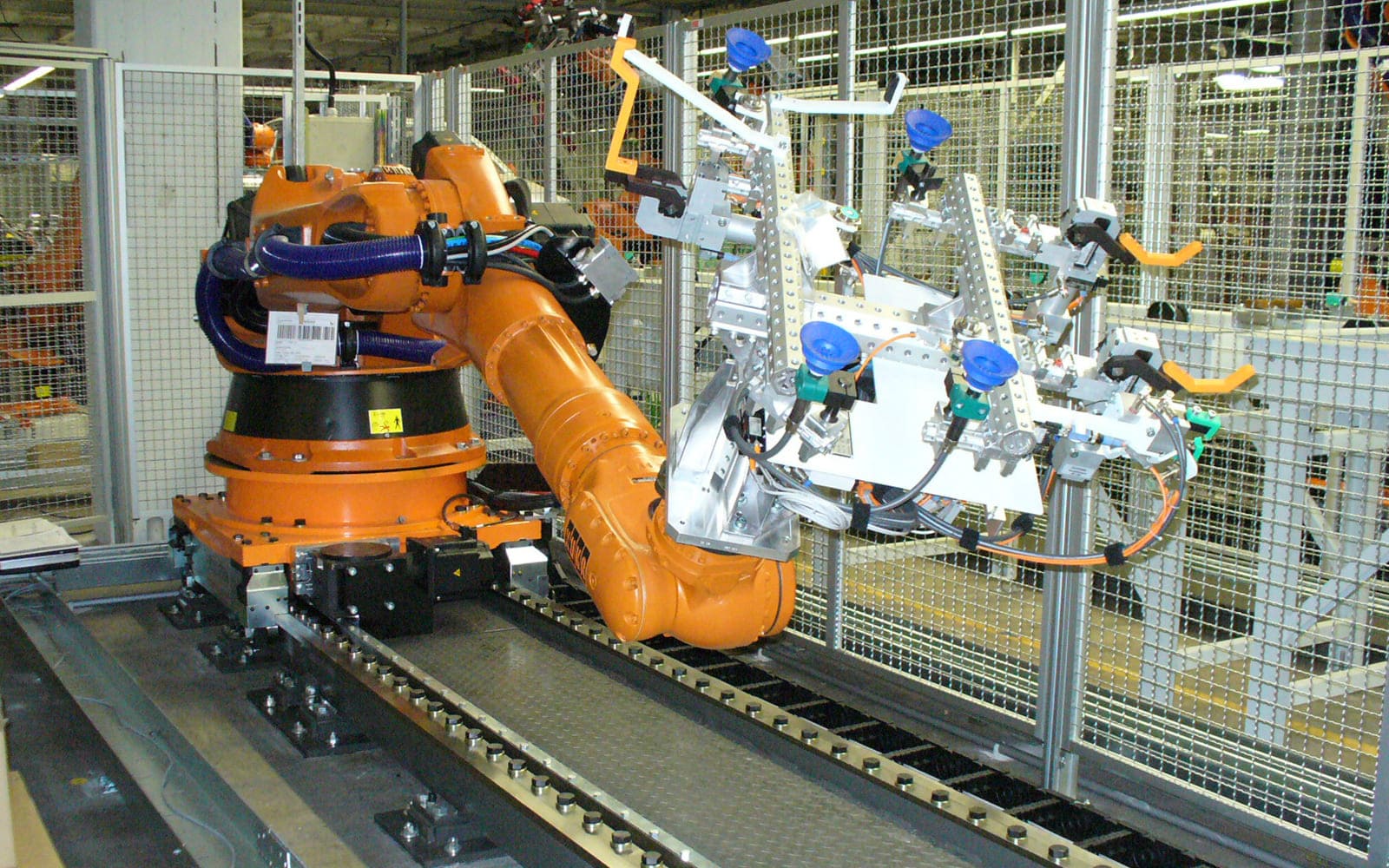

ZOLLERN robot traverse axes (ZRV) can be used for robots of all manufacturers, such as ABB, Kuka, Fanuc and Stäubli. The robot traverse axes are developed and produced for systems in the automotive industry, the aerospace industry, the machine tool and metalworking industry, the construction industry, the food industry and other industries.

ZOLLERN jig axes (ZVA) are suitable for tool and jig changing as well as transporting large parts with a transport weight from 100 to 15,000 kg. The jig axes are developed and produced for systems in the automotive industry, the aerospace industry, the machine tool and metalworking industry, the construction industry, the food industry and other industries.

Product examples

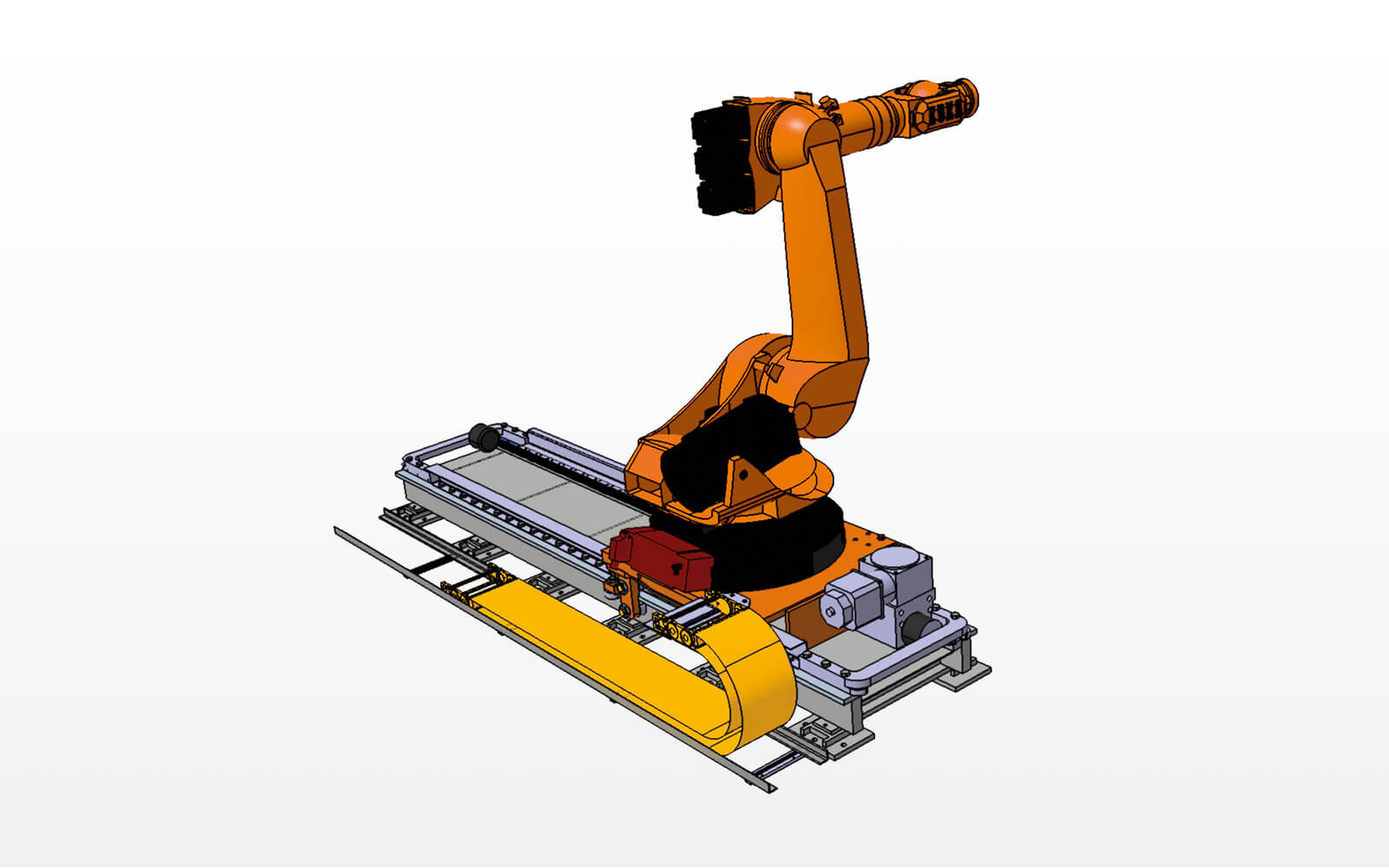

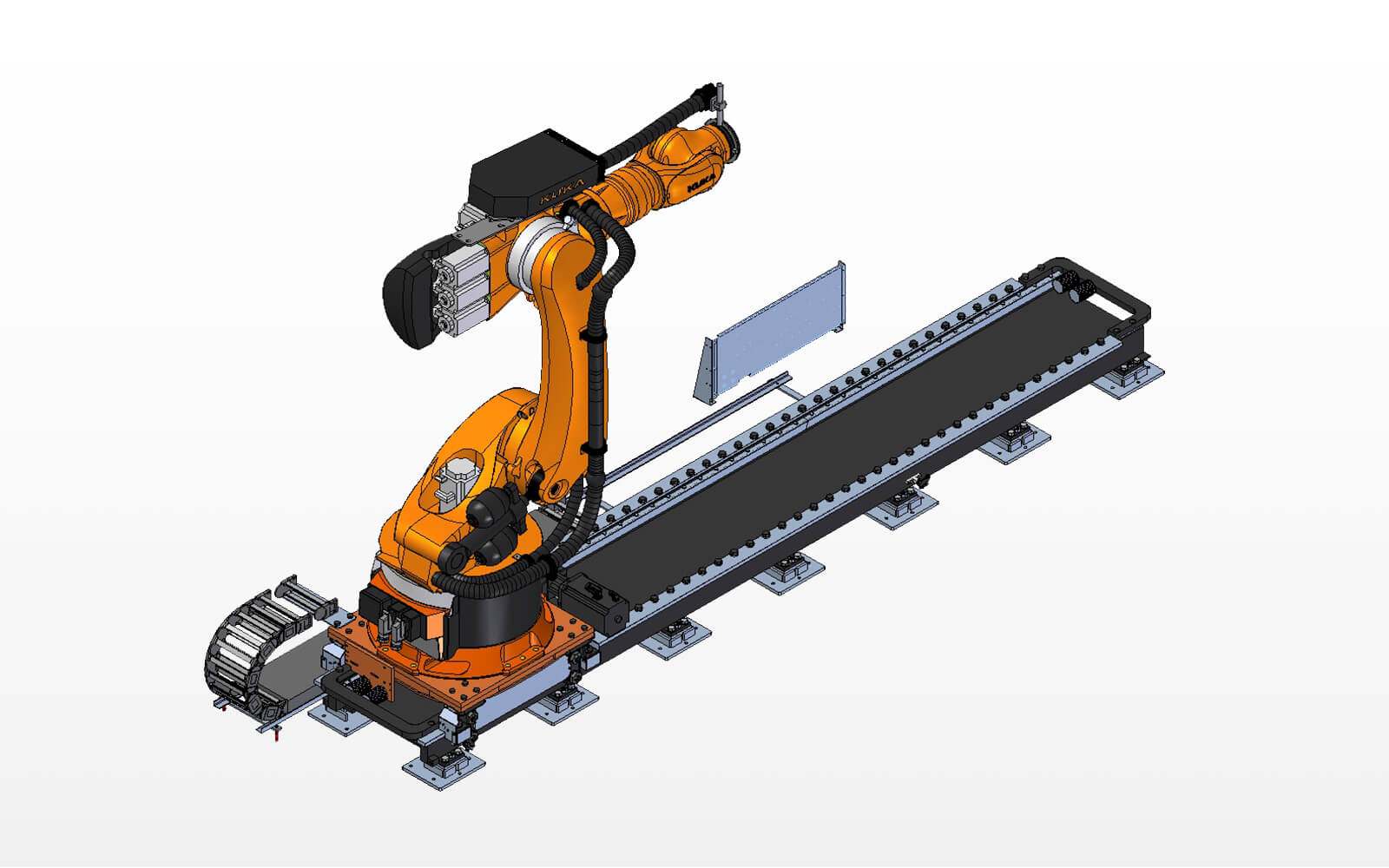

ZRA version

Robot traverse axes version

- Base support in solid welded steel design

- Hardened and ground flat guides

- Dirt scraper systems on roller blocks

- Torsionally-stiff, solid traversing carriage for receiving the robot

- Traversing carriage with individual and easily exchangeable roller blocks

- Drive via pinion and rack with powerful drive motors

- Also available as a special design

- Installation position on the ground, elevated, on the ceiling or on the wall

- Bending and torsionally stiff design

Technical Data ZRA

Technical data for the robot traverse axes

| Maximum bearing load: | up to 6,000 kg |

| Mass of carriage: | 550 kg |

| Power transmission: | Rack and pinion, helical cut or via belt |

| Travel speed: | 1.5 – max. 3 m/s |

| Max. acceleration: | 1 - 5 m/s² |

| Repeat accuracy: | +/- 0.02 mm |

| Nominal stroke, min.-max: | 1,000 - 40,000 mm |

| Nominal stroke stepping: | 500 mm |

| Installation position: | Ground, wall, ceiling |

| Installation height: | Standard 500 mm, as special solution 200 mm |

| Range of use: | 7th axis, can be used for welding applications |

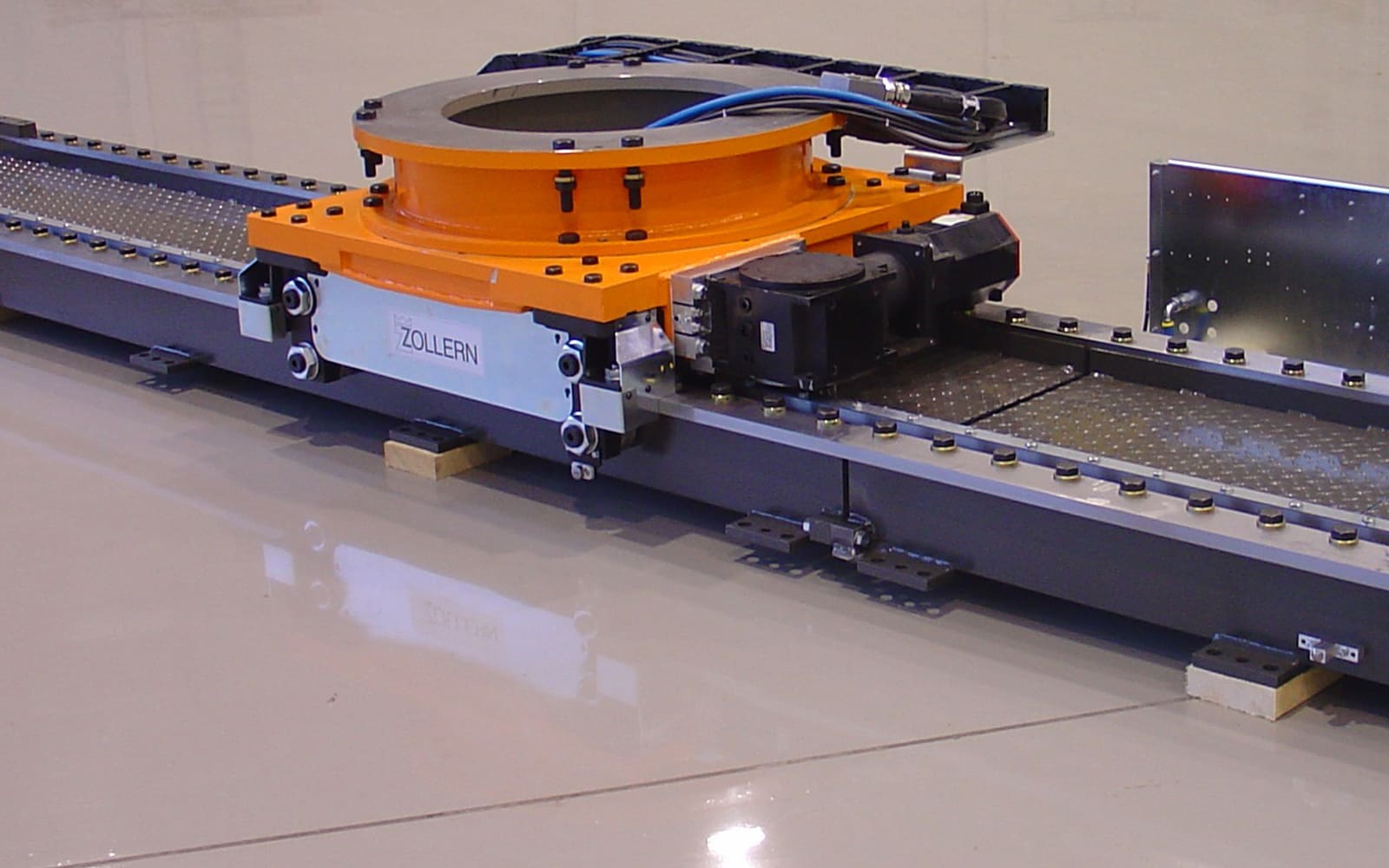

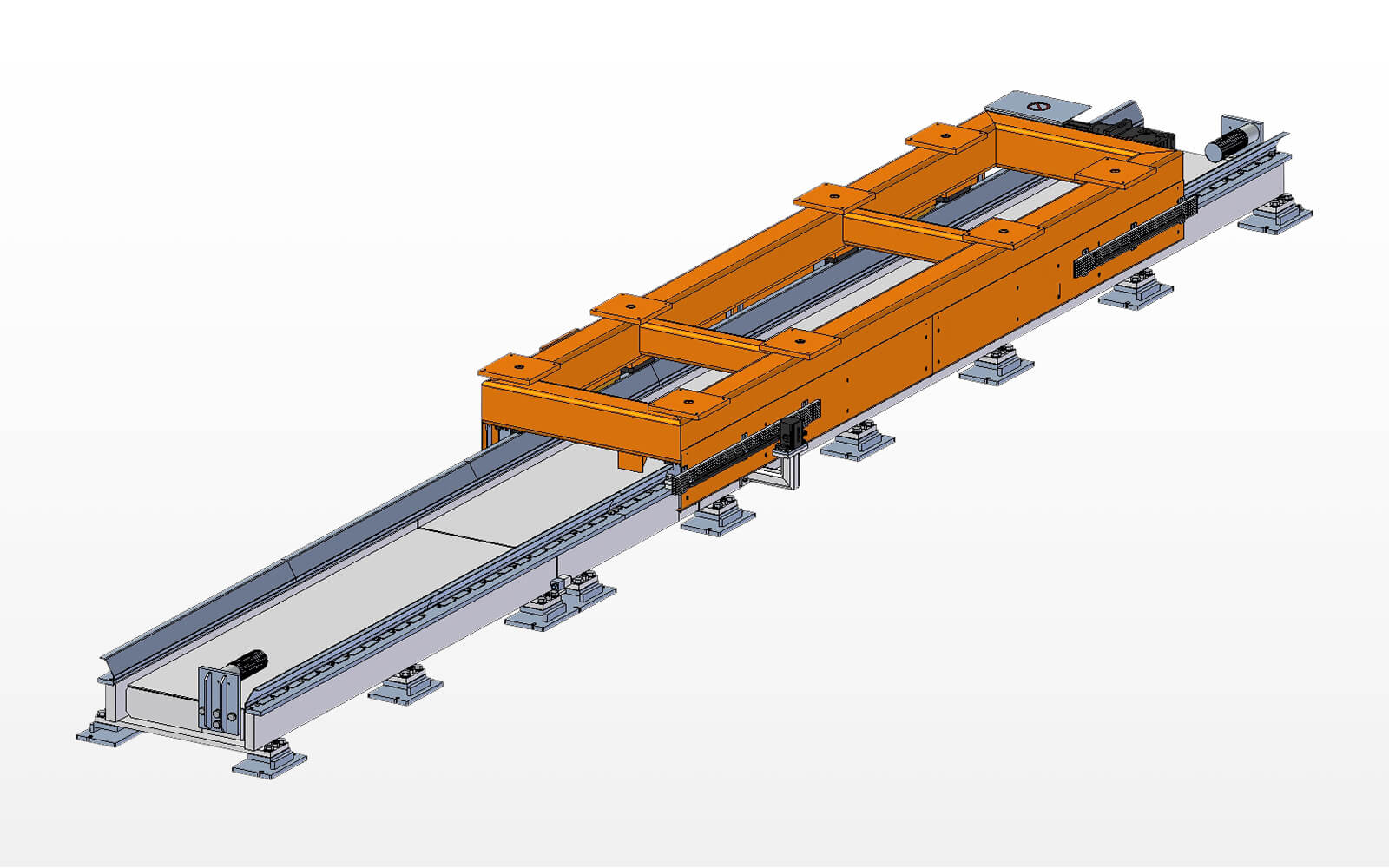

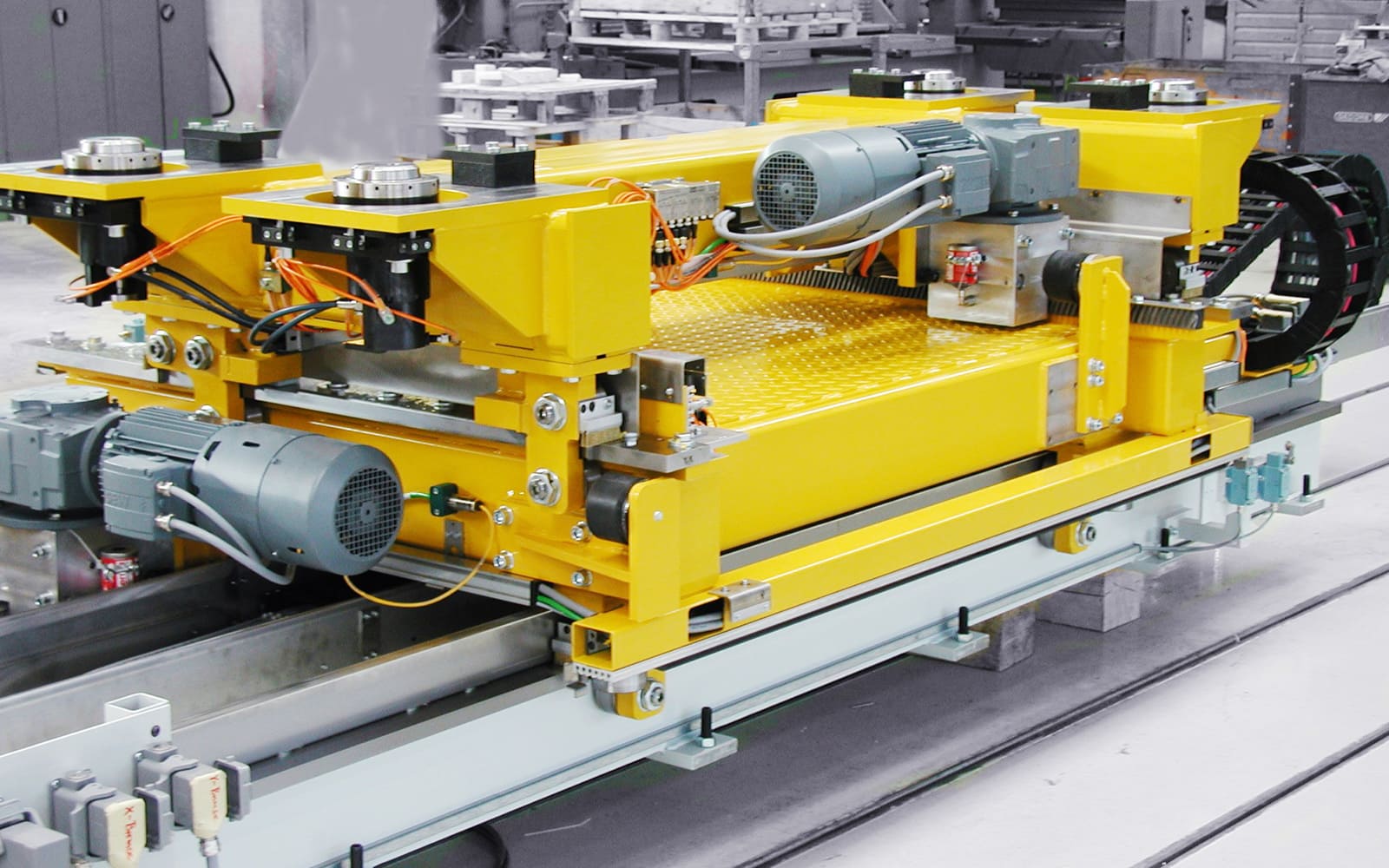

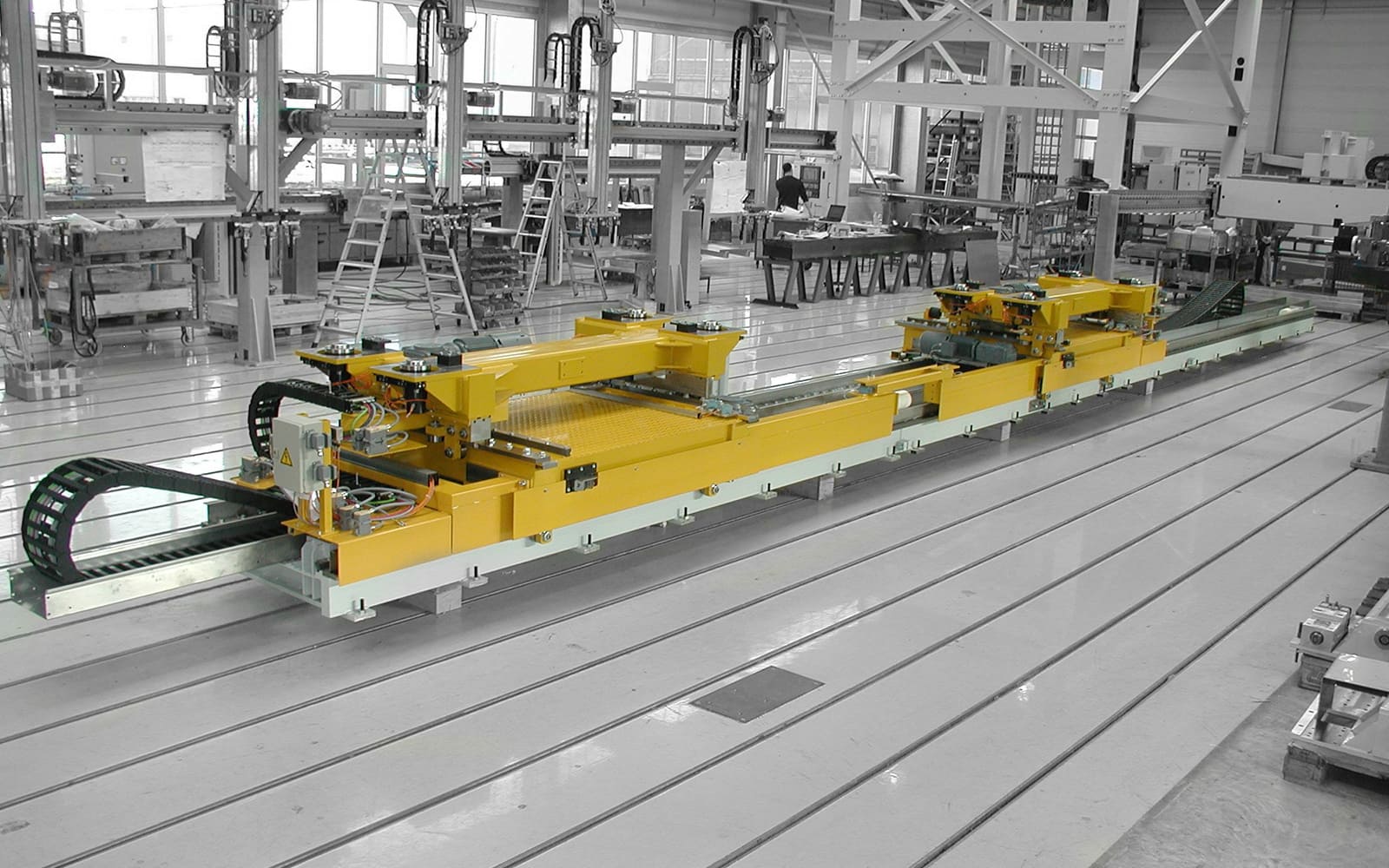

ZVA version

Jig axes version

- Base support in solid welded steel design

- Hardened and ground flat guides

- Dirt scraper systems on roller blocks

- Torsionally-stiff, solid steel tube frame carriage for holding the jig

- Carriage with individual and easily exchangeable roller blocks

- Drive via pinion and rack with powerful drive motors

- 1 to 3 carriages coupled or individually movable (payloads of jig approx. 500 kg - 15,000 kg)

- Jig size up to approx. 100 x 5,000 mm long and 1,000 x 2,000 mm wide

- Repeat accuracy

+/- 0.3 mm without pneumatic stakeout

+/- 0.05 mm with pneumatic stakeout - Axis height of ground - OK frame approx. 200 mm - 600 mm or higher

- Can be combined as a surface system with parking stations or storage systems