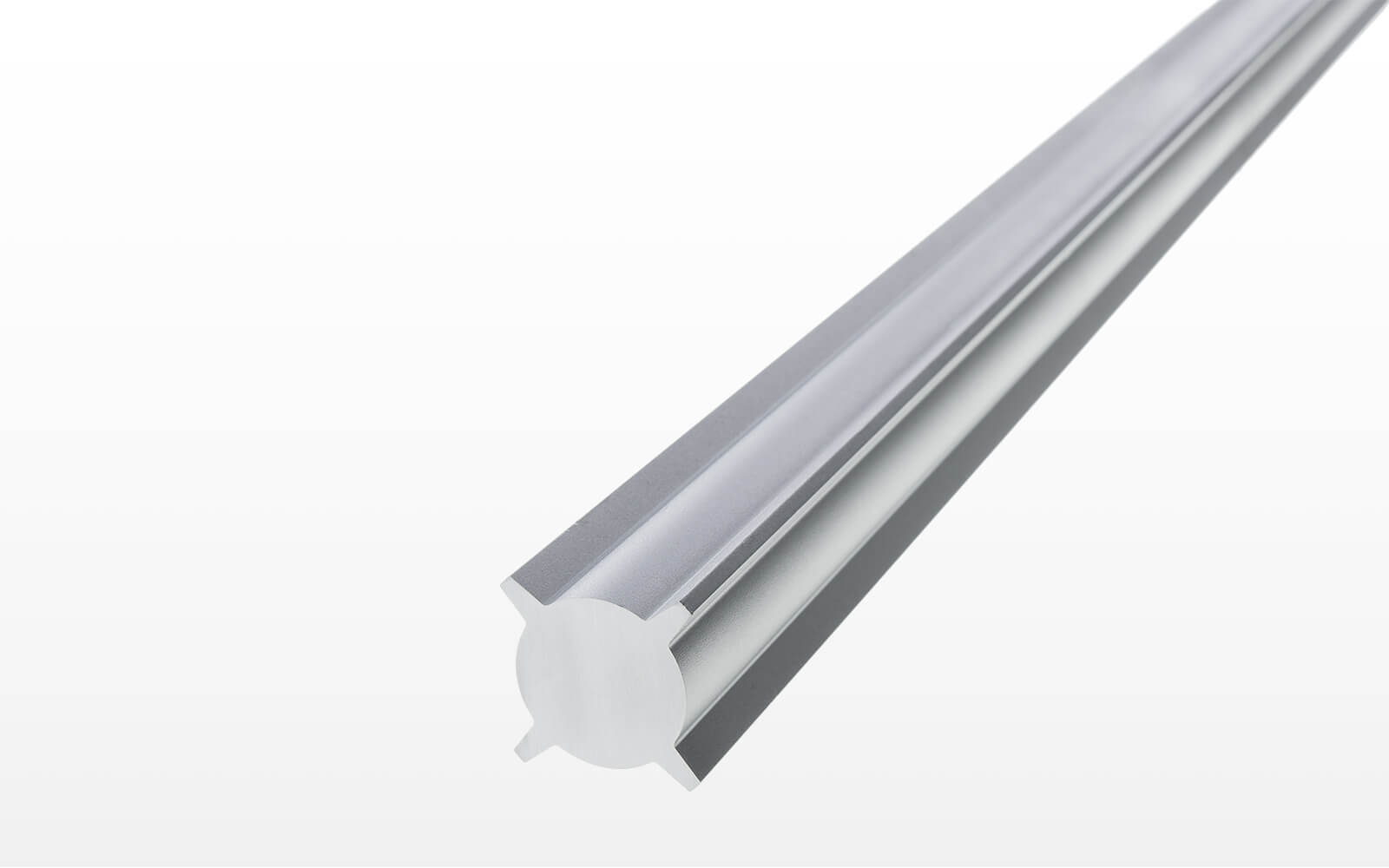

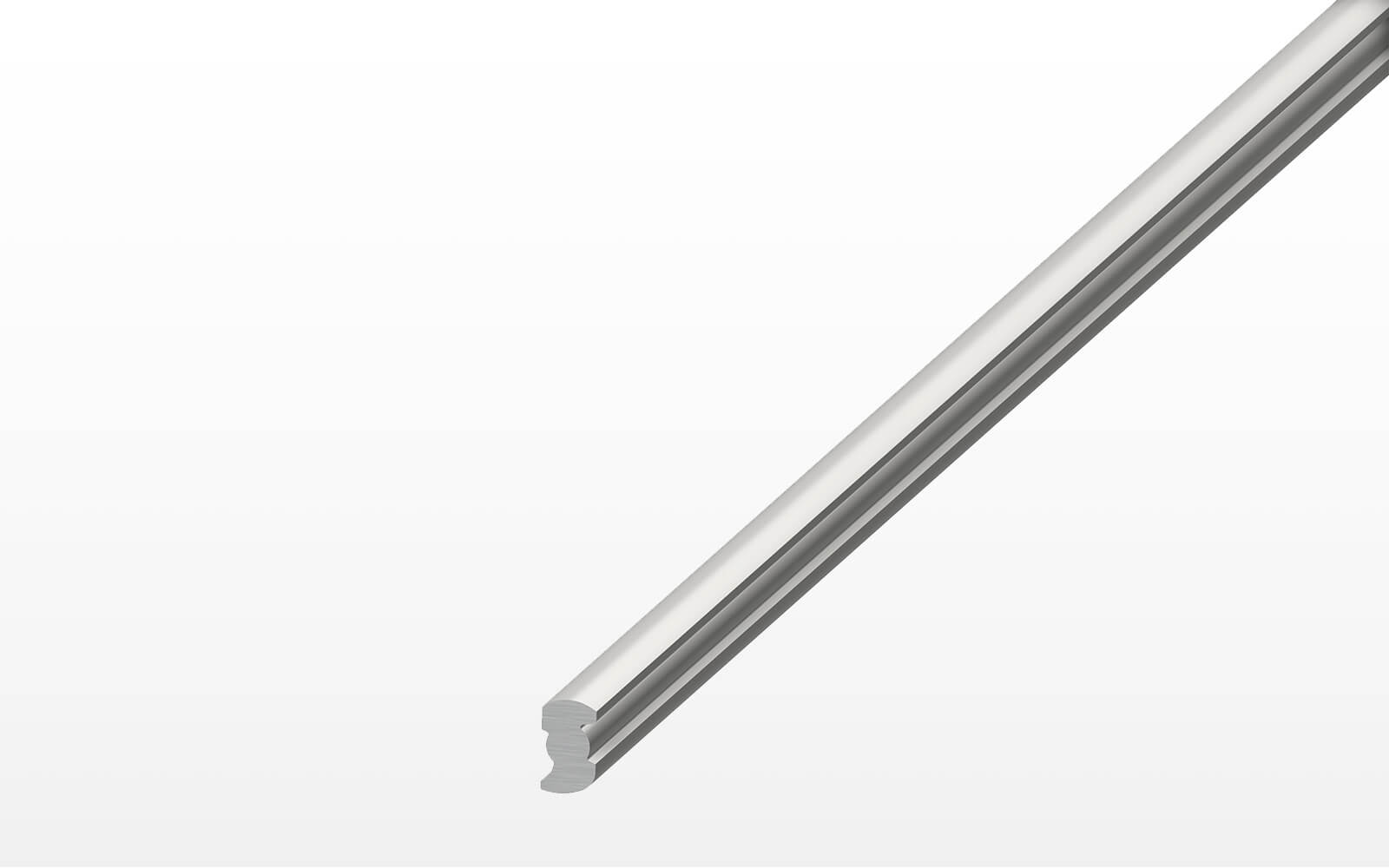

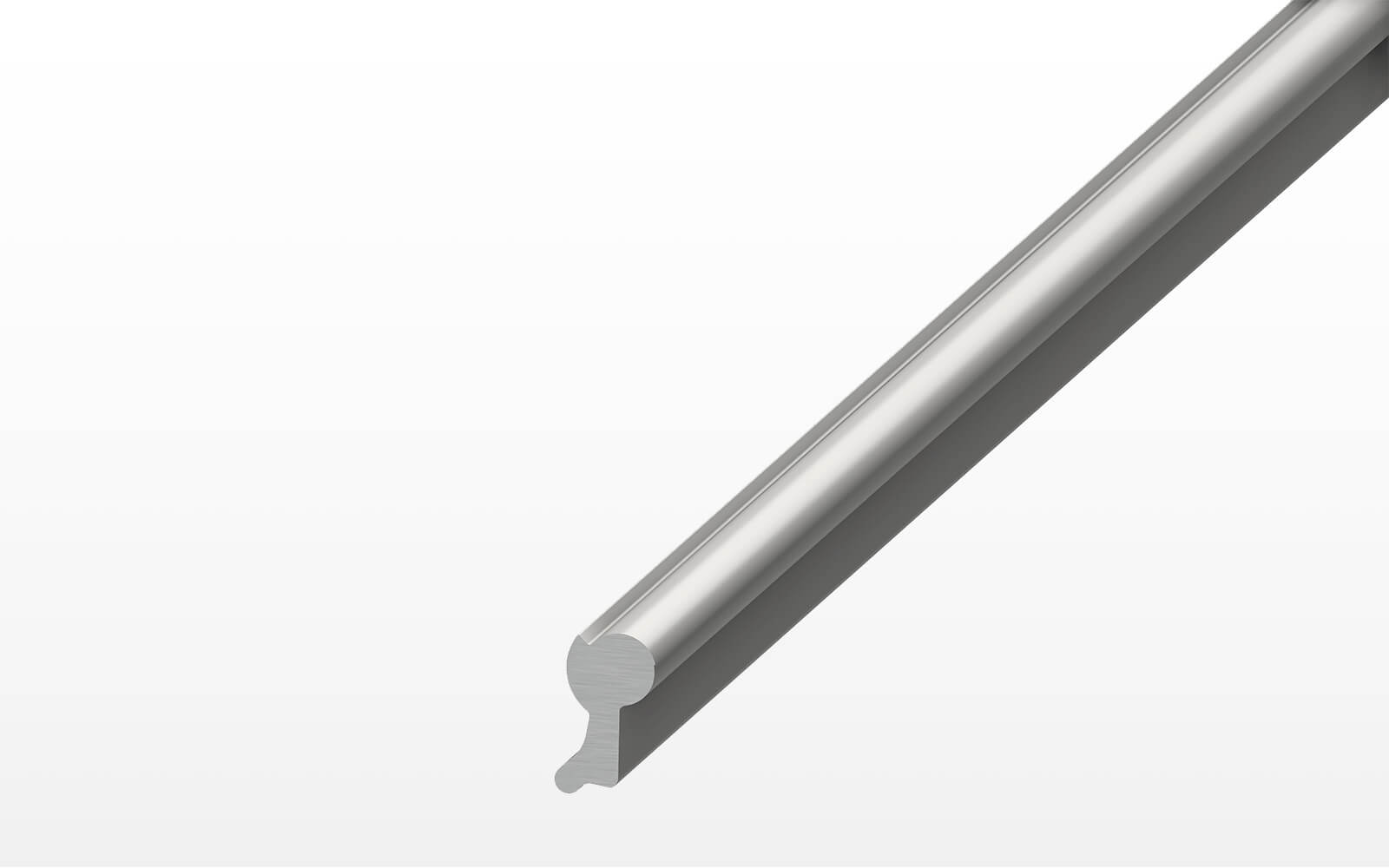

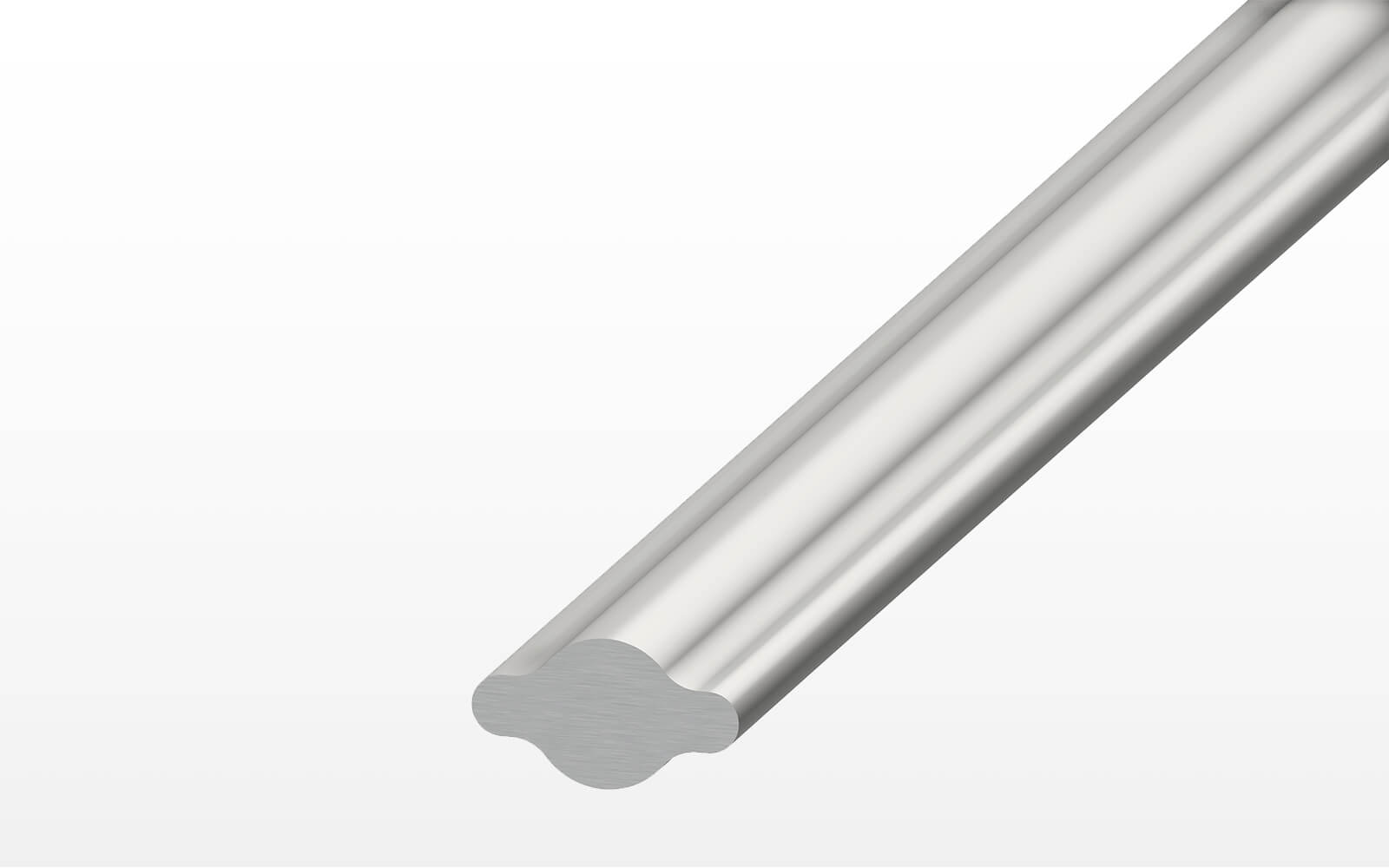

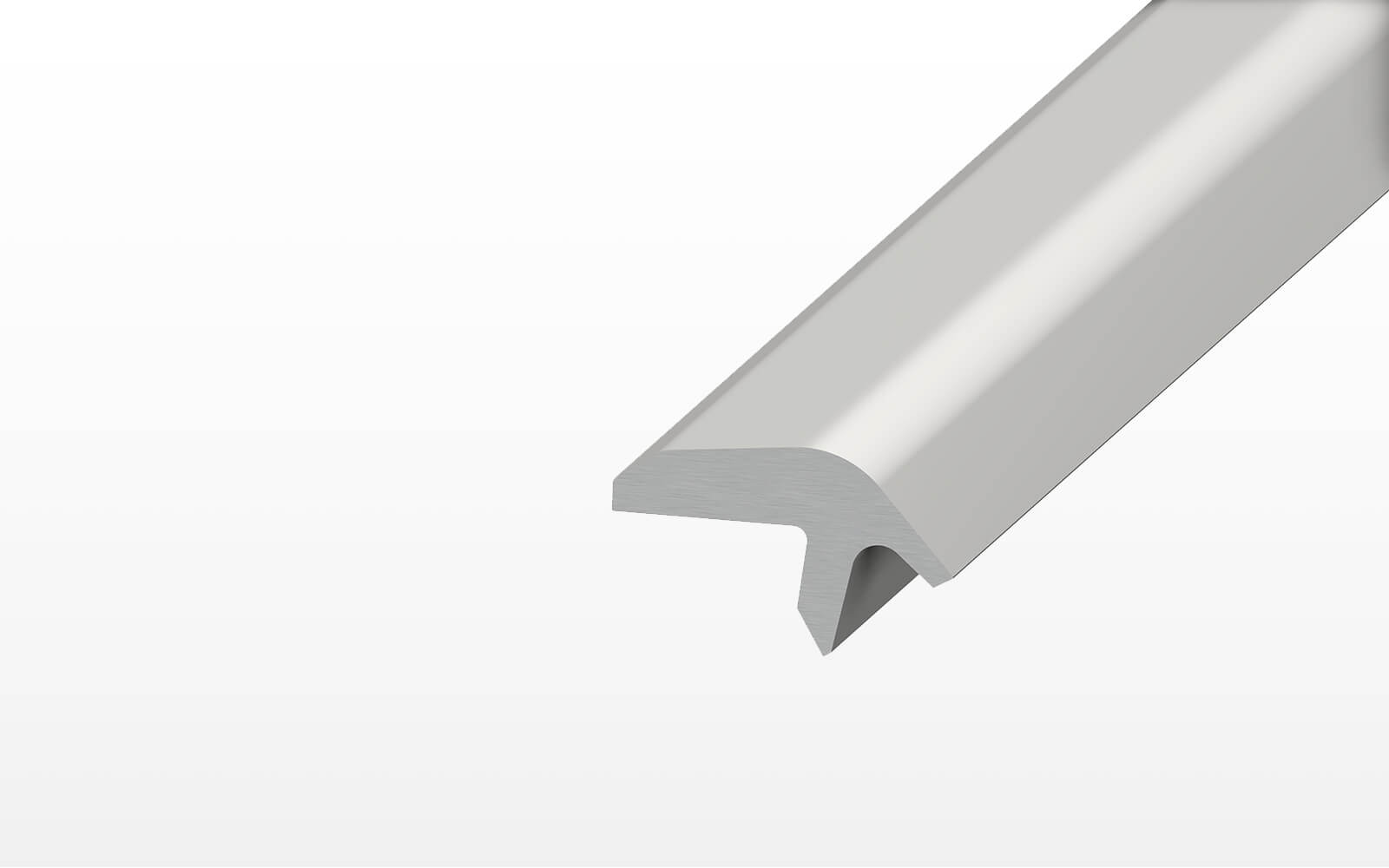

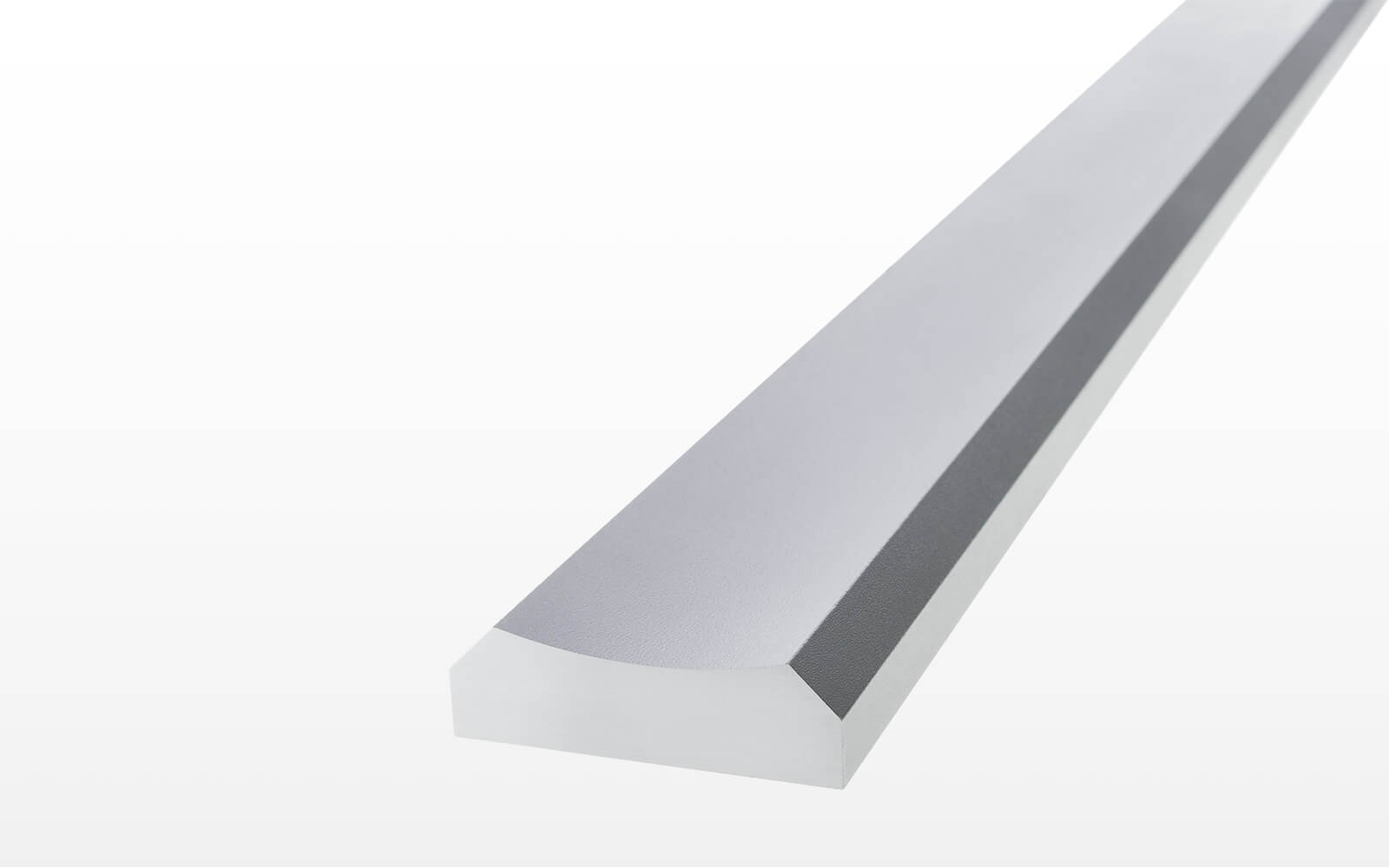

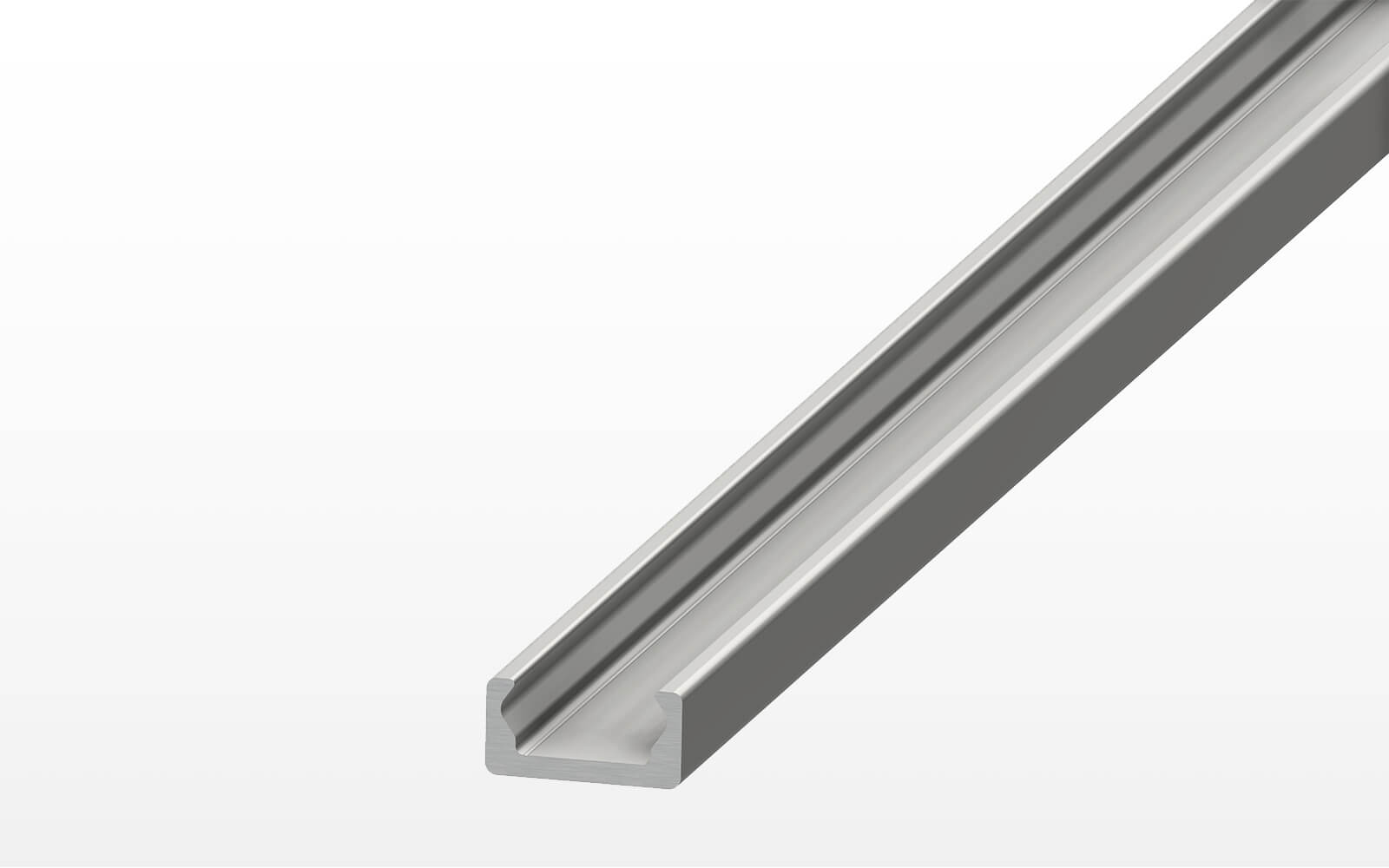

The individual and precisely pre-formed special profiles are supplied as rings, coils or bars. One ideal application area of sectional steel is components with complex shapes, which have to withstand high loads.

Features and advantages

- Excellent material properties thanks to the combination of hot rolling, cold forming and heat treatment

- High wear resistance thanks to optional inductive hardening with hardening depths from 0.5 to 5 mm

- Strength 1200 MPa after cold drawing

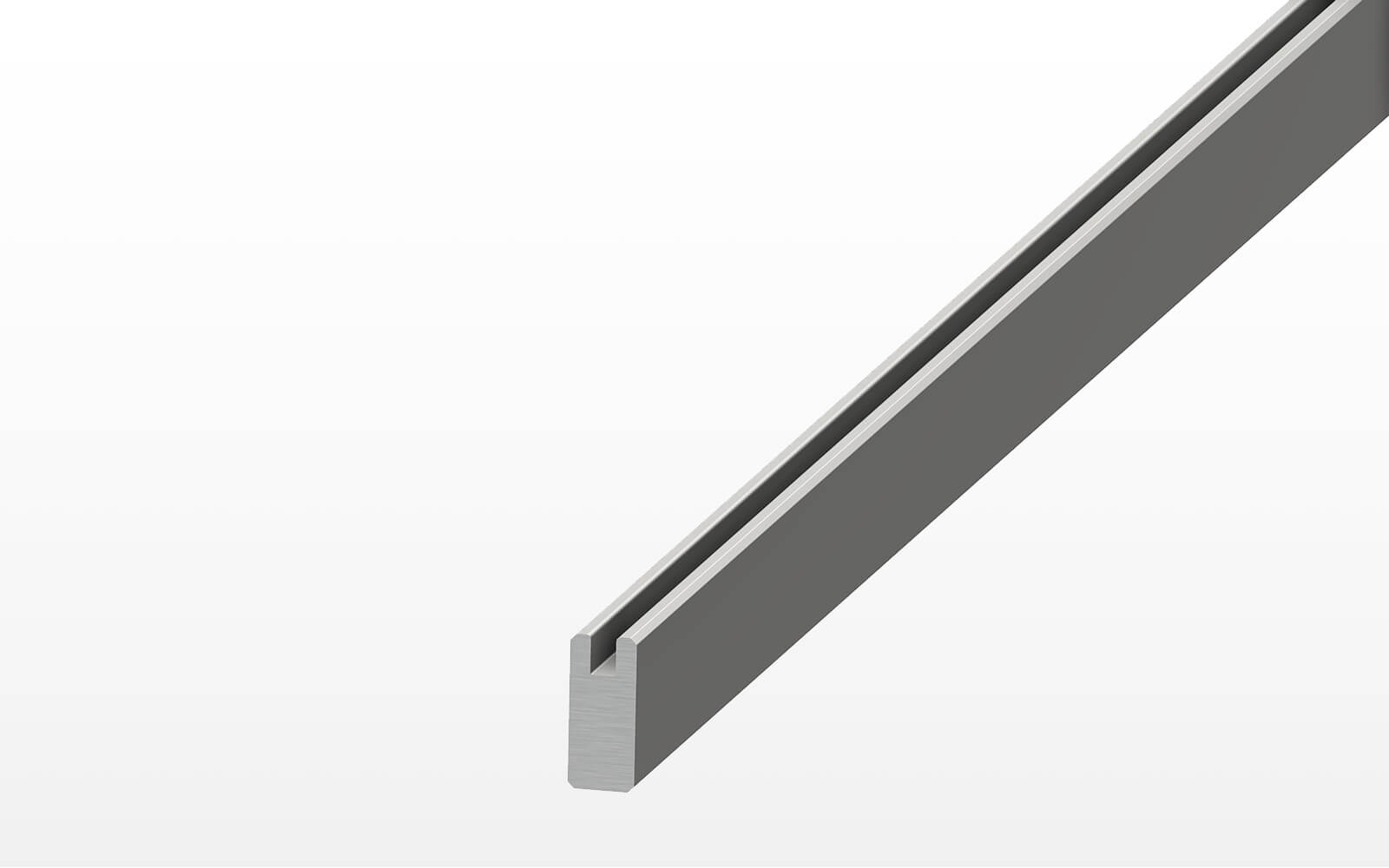

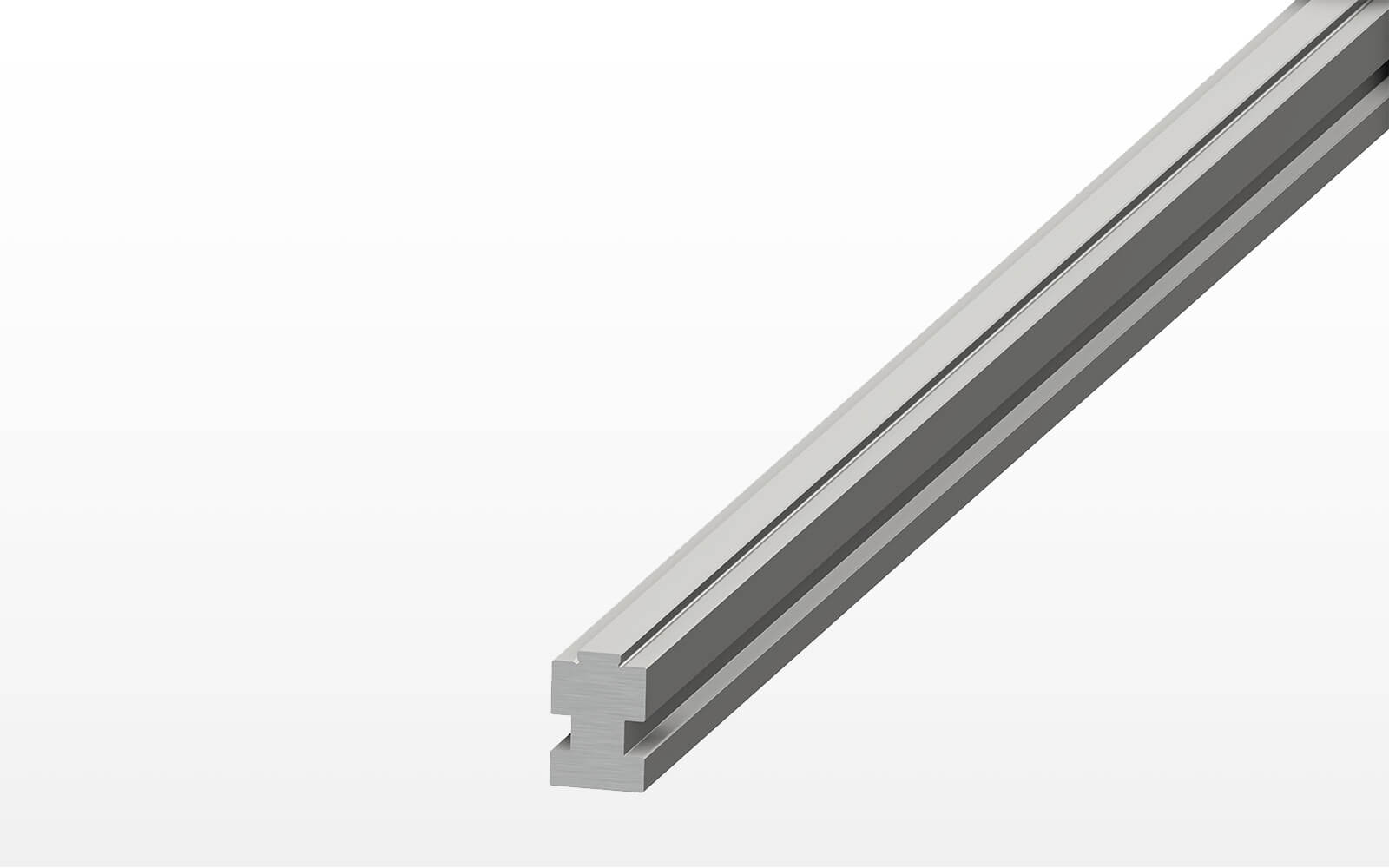

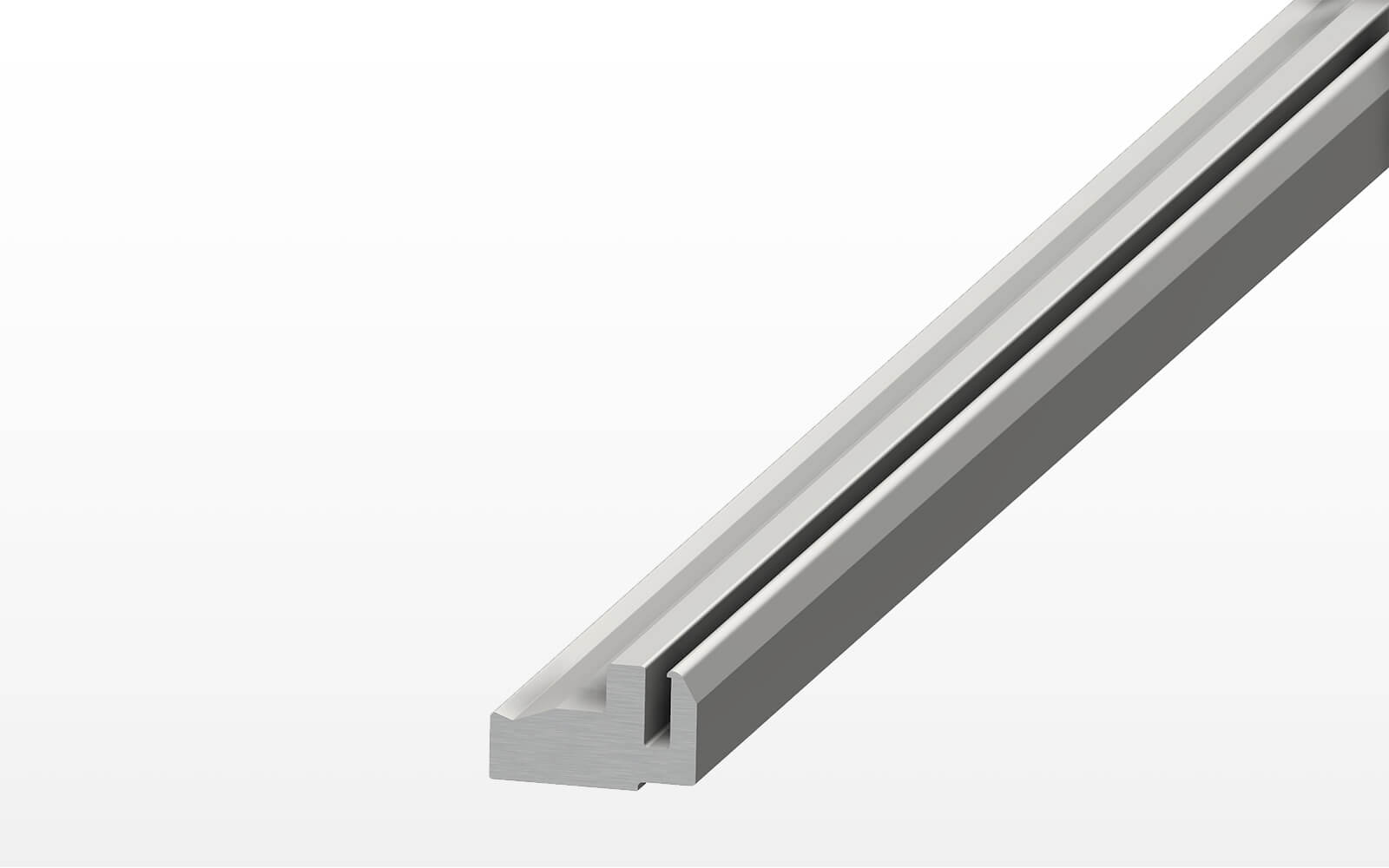

- High level of variety in geometric design

- Perfect dimensional accuracy

- Heat treatments under inert gas

- Potential to reduce costs through near-net-shape production

- 60% material savings compared to machining processes

- Hollow profiles with internal geometry or welded profiles are also available

Technical Data

Forms of delivery: Rings up to 2 tonnes, bars up to 12 m

Profile versions: hot-rolled, cold-rolled, cold-drawn, inductively hardened

Profile cross-sections: 5 to 7,650 mm² (40 g/m to 60 kg/m)

Dimensional tolerances: from 20 µm

Surface roughness: from Rz 5 µm

Straightness, torsion: from 0.2 mm/m

Inductive surface hardening and through-hardening: Achievable hardness of up to 64 HRC, hardening depth 0.5 to 5 mm

Materials

Experienced ZOLLERN experts choose the appropriate material from a wide range of steels and steel alloys in order to meet the requirement that will be placed on the profile.

Hundreds of steel grades and other materials are available to choose from. For the steels, we use structural steels, machining steels, case-hardening steels, heat-treatable steels, rolling bearing steels, tool steels and stainless (austenitic, ferritic and martensitic) steels.

Processes

The profiles run through different processes in production, which are tailored to the desired profile properties.

Further machining is optionally carried out with various methods to produce customer-specific components that are ready to install by customer request.

- Hot rolling

- Cold rolling

- Cold drawing

- Inductive hardening

- Mechanical processing

- Heat treatment

- Surface treatment

- Assembly

Service / added value

ZOLLERN offers extensive additional services and added value

- Development partnership - from the idea to the finished product

- Technical consultation, from the material selection to material properties to the profile design

- Application-specific solutions, extensive variety in design

- High quality and reproducibility

- High vertical range of manufacture and many years of experience

- Own toolmaking and therefore delivery times independent of third parties

- Customer-specific version, such as hollow profiles with internal geometry or welded profiles

- Constant continued development of the processes

- Steel profiles

- Profiles for automotive industry

- Profiles for construction industry

- Profiles for energy industry

- Profiles for linear guides

- Profiles for mechanical engineering

- Profiles for textile machinery

- Profiles for weapons technology

- Steel profiles materials

- Inductive hardening

- Flip catalogue materials steel profiles